Underground Flexible Fire Resistant Cable Duct

Product description

Product Description

Specifications

Underground Flexible Fire Resistant Cable Duct

1.Material:PVC

2.Thickness:0.40mm~2.0mm

3.Standard:EN/13245-2/2005

Underground Flexible Fire Resistant Cable Duct

1. Product Description

| Impact strength | Resistant to compression and impact, suitable to be buried in concrete |

| Non-conductive | Good insulation, able to resist 25KV voltage, assuring a safe system |

| Fire resistance | with self-extinguishing function |

| Corrosion Resistance | Resistant to acids, bases and salts, assuring a lower maintenance cost and a longer performance life |

| Smooth surface | Small friction and high flow capacity to ensure the cables go through smoothly |

| Easy Installation | Light weight, easy to cut, transport, bent and handle; easy connecting by solvent cement and threading joining without leakage |

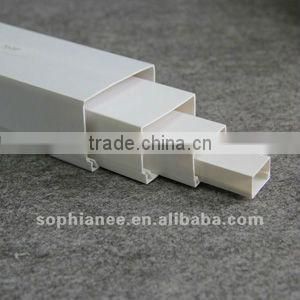

2. Trunking Specification and Custom Size Accepted

| Item | Size(W*H)mm | Thickness(mm) |

PVC Trunking

| 10x10 | 0.60 |

| 15x10 | 0.55/0.80 | |

16x16

| 0.58/0.63/0.80/1.00 | |

| 18x9 | 0.40 | |

| 20x10 | 0.45/0.55/0.70 | |

| 20x12 | 0.50/0.60/0.80 | |

| 23x13 | 0.65/0.75 | |

| 24x14 | 0.65/0.7 | |

| 25x16 | 0.63/0.72/1.00 | |

| 25x25 | 0.75/0.95 | |

| 30x15 | 0.60/0.76 | |

| 39x19 | 0.75/0.90 | |

| 40x16 | 0.60/0.80/1.00 | |

| 40x25 | 0.68/0.76/1.00/1.20 | |

| 40x30 | 1.00/1.20 | |

| 40x40 | 1.38 | |

| 50x25 | 1.00 | |

PVC Square Trunking

| 50x50 | 1.10/1.25 |

| 59x22 | 0.85/1.10 | |

| 60x30 | 1.10 | |

| 60x40 | 1.20/1.40 | |

| 60x60 | 1.68 | |

| 75x50 | 1.25 | |

| 75x75 | 1.30/1.50 | |

| 80x40 | 1.35 | |

| 80x50 | 1.40/1.70 | |

| 99x27 | 0.90/1.20 | |

| 100x40 | 1.35/1.50 | |

100x50 | 1.35/1.70 | |

| 100x60 | 1.65/1.90 | |

| 100x75 | 1.65/2.00 | |

| 100x100 | 1.60/2.00 | |

| 100x150 | 2.00 | |

PVC ARC-Floor Trunking

| 35x10 | 1.75 |

| 50x15 | 1.60 | |

| 70x20 | 2.00 | |

Special PVC Trunking

| 100x50 | 1.35 (three spacers) |

100x50 | 1.35 (four spacers) | |

Customized

| Accepted | |

3. Our Advantage

1) Machinery: More than 60 advanced Extrusion machine and 30 Injection

machine with max 500T.

2) Experience: Over 30 years of experience in Thermoplastic Extrusion and Injection, such as running temperature control and continuously formula optimization.

3)Quality Assurance: 24-hour Rigorous QC Team which is in line with ISO 9001 Certification;

Large-scaled Mould Workshop: with 4 senior mould designers and a team of experienced mould manufacturing technicians.

4)International Projects: Supply building and irrigation Projects in Asia, Africa, Middle East, Russia and other countries .

Product Showing

Our Factory

Our Certification

Recommended products