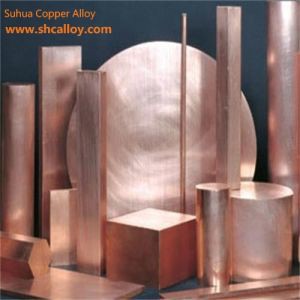

China Best Chromium Copper Alloy for Making Molds

Product description

Chromium copper is used to ensure the performance through the combination of heat treatment and cold processing. It can obtain the best mechanical and physical properties. Therefore, it is used as a resistance welding electrode for general purposes, mainly as an electrode for spot welding or seam welding of low-carbon steel and coated steel plate, as well as an electrode holder, shaft and gasket material for welding low-carbon steel, or as a large mold, fixture for projection welding machines, mold or inlaid electrode for stainless steel and heat-resistant steel.

At room temperature and higher temperature (400 ° С) It has high strength and hardness, good electrical conductivity and thermal conductivity, good wear resistance and antifriction. After age hardening treatment, the strength, hardness, electrical conductivity and thermal conductivity are significantly improved, and it is easy to weld and braze. It has good corrosion resistance in atmosphere and fresh water, good high-temperature oxidation resistance, and can withstand pressure processing in cold and hot states, but its disadvantage is that it is sensitive to notch, Stress concentration at notch and sharp corner is easy to cause mechanical damage. Therefore, it is not suitable to make commutator slices.

Recommended products