High Quality graphite spray lubricant Graphite Wear Resistance Metal Anti-Wear Gear Grease

Product description

The application of graphite lubricants is direct, typically involving the direct application of dry powder or paste to surfaces that require lubrication. Graphite particles adhere to the metal surface, forming a protective and lubricating layer to reduce friction and wear. Depending on the operating conditions and degree of wear, it may be necessary to reapply regularly.

One of the main advantages of graphite lubricants is that they can provide lubrication without the need for traditional wet oil or grease. The drying characteristics of graphite lubricants make them highly suitable for environments where liquid lubricants may attract dust, dirt, or pollutants, thereby increasing maintenance requirements and potential performance issues.

Graphite lubricant, commonly known as dry lubricant, is a multifunctional and efficient solution for reducing friction and improving the performance of various mechanical systems. These lubricants are mainly composed of graphite particles and have a dry and smooth coating, which can reduce wear, prevent jamming, and improve overall efficiency in a wide range of applications.

Graphite lubricant, as an efficient and multifunctional lubricating material, has the characteristics of high temperature stability, good lubrication performance, and environmental safety. It is widely used and plays an important role in various fields such as mechanical manufacturing, metallurgical industry, and aerospace. With the continuous progress of technology and the continuous development of the industrial field, the application prospects of graphite lubricants will be even broader. I believe that in the future, graphite lubricants will continue to contribute more to the development of the industrial sector.

In metallurgical processes, graphite lubricants can be used for lubrication and protection of high-temperature furnaces, preventing furnace wear and oxidation. At the same time, it can also reduce the viscosity of the metal melt and improve smelting efficiency. Graphite lubricants are also widely used in the aerospace field. It can be used for lubrication of key components such as aircraft engines and rockets, ensuring stable operation of equipment under extreme conditions such as high temperature, high speed, and high load.

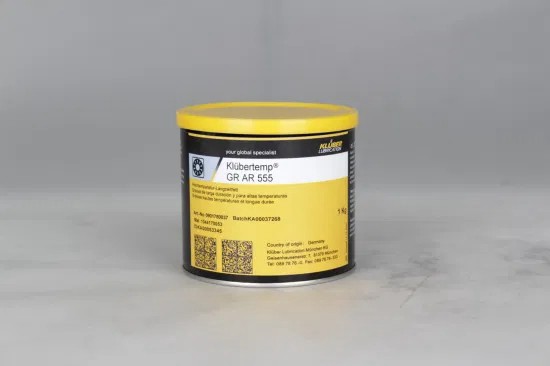

Recommended products