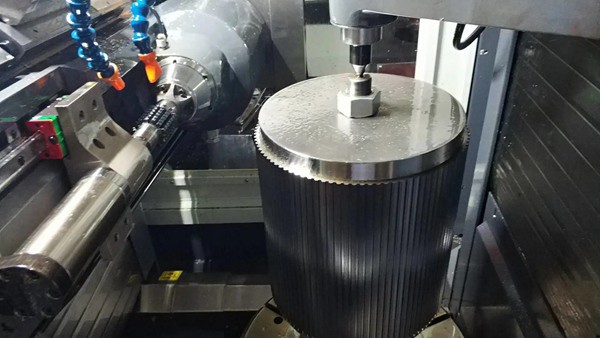

Automatic CNC Special Spline Hobbing Machine for Gear Processing Cutting Hobber

Product description

The hobbing machine generates less cutting heat during the machining process, and the cutting force is dispersed at multiple rolling points, which helps to reduce energy consumption and environmental pollution. Gear hobbing machines have an irreplaceable position in the field of gear processing due to their advantages of high precision, high efficiency, good surface quality, wide adaptability, easy operation, and energy conservation and environmental protection. With the continuous development and technological progress of the manufacturing industry, gear hobbing machines will continue to play an important role in the field of gear processing.

Gear hobbing machines can be divided into two types according to layout: vertical and horizontal. Large and medium-sized gear hobbing machines are mostly vertical, while small gear hobbing machines and gear hobbing machines specifically designed for processing long shaft gears are both horizontal. Vertical gear hobbing machines are divided into two types: worktable movement and column movement. In practical applications, choose the appropriate type of gear hobbing machine based on processing requirements and workpiece characteristics.

Recommended products