Automatic Spray Filling Capping Machine with CE and ISO

Product description

As one of the important equipment in modern industrial production, liquid filling machines will continue to play an important role in improving production efficiency and ensuring product quality. Meanwhile, with the continuous progress of technology and changes in the market, liquid filling machines will also continue to develop and innovate, providing more efficient, accurate, and environmentally friendly liquid packaging solutions for various industries.

Liquid filling machines can further improve the automation level of equipment, reduce manual intervention, lower production costs, and improve production efficiency. Pay attention to environmental protection requirements such as energy conservation, emission reduction, and waste disposal, and promote the green manufacturing and use of equipment. Provide more personalized customized services based on customer needs and market changes to meet their special needs.

Application field:

Food industry: filling of beverages, jams, seasonings, etc.

Beverage industry: filling of various bottled and canned beverages.

Chemical industry: filling of paints, coatings, inks, etc.

Cosmetic industry: filling of products such as shampoo, shower gel, skincare products, etc.

In modern and automated industrial production, liquid filling machines play a crucial role. Whether in the food, beverage, cosmetics, or chemical industry, liquid filling machines are one of the key equipment to ensure product quality and improve production efficiency. This article will provide a detailed introduction to the working principle, characteristics, application areas, and future development trends of liquid filling machines.

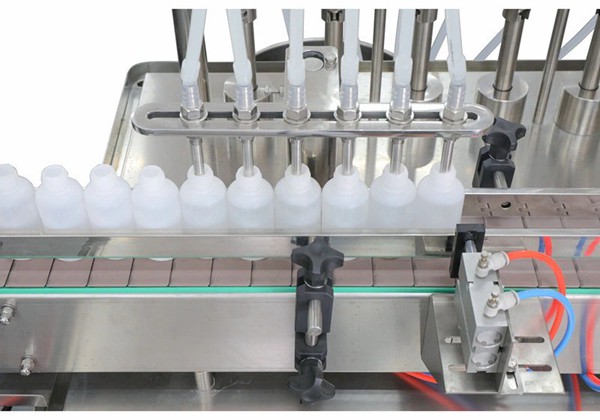

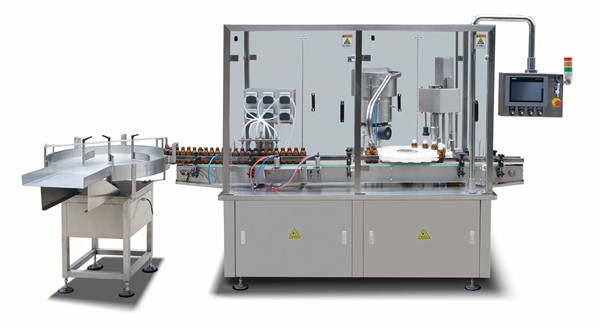

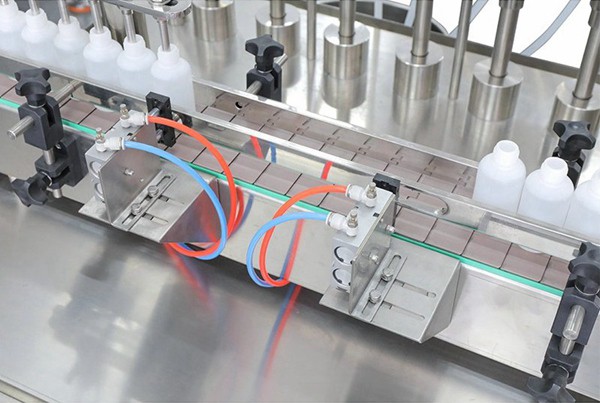

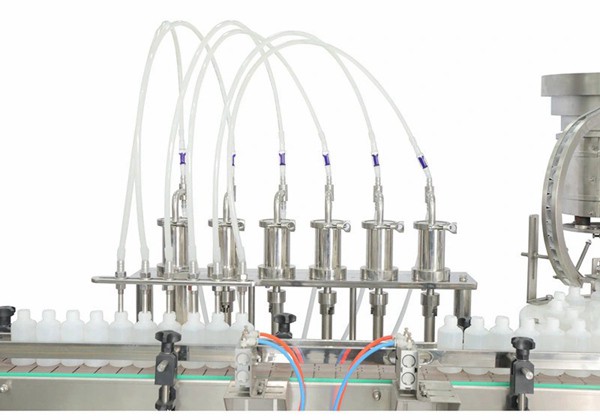

The capping filling machine is an automated machine equipment specifically designed for filling and capping liquid products. It combines two major functions of filling and capping, which can achieve efficient and accurate filling of liquid products and automatic sealing of bottle caps. The capping filling machine can automatically fill liquid products according to the preset filling capacity and speed, improving production efficiency and accuracy.

Recommended products