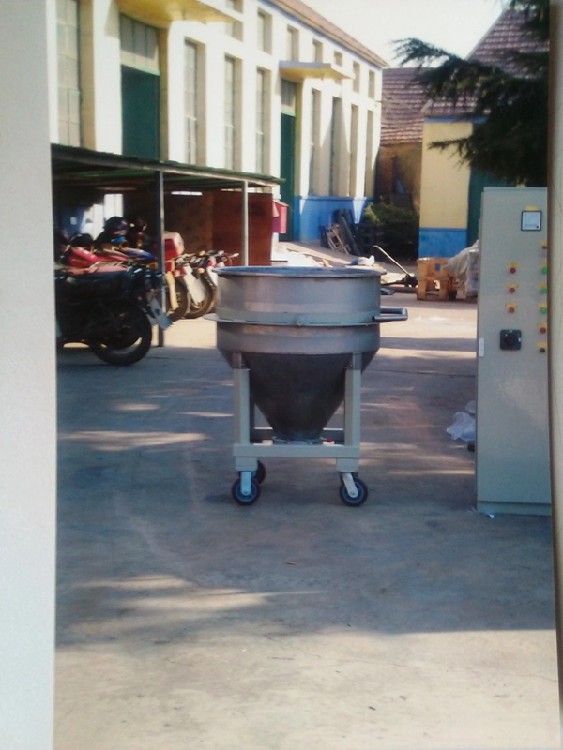

Wholesale Powder Coating Production Equipment Mixer

Product description

In the process of coating production, the role of the coating mixer cannot be ignored. It can not only ensure the uniform mixing of coating materials, but also improve the quality and performance of coatings. Therefore, choosing a high-performance coating mixer is crucial for coating production enterprises. Meanwhile, with the continuous development of the paint industry, the technology and performance of paint mixers are also constantly improving to meet the industry's demand for high-quality coatings.

The mixing bucket and mixing device are made of wear-resistant and corrosion-resistant materials, which can adapt to the mixing needs of various coating materials and ensure the long-term stable operation of the equipment. The paint mixer can adapt to the mixing needs of different paint raw materials, and can achieve ideal mixing effects for both liquid and powder coatings.

The paint mixer can achieve uniform mixing of paint raw materials in a short period of time and improve production efficiency through carefully designed mixing devices and control systems. The control system adopts advanced automation technology, making the operation of the paint mixer more convenient and feasible.

The working principle of the paint mixer is relatively simple and efficient. When the coating raw materials enter the mixing drum through the feeding system, the control system starts the motor to drive the mixing device to start working. The mixing device forms convection and shear effects on the coating raw materials in the mixing drum through rotation or vibration, thereby achieving uniform mixing. When the mixing reaches the predetermined uniformity, the control system turns off the motor, opens the discharge system, and discharges the mixed paint.

The working principle of the powder coating mixer is relatively simple. When the coating raw materials are added to the mixing drum through the feeding port, the control system starts the motor to drive the mixer to rotate at high speed. The agitator pushes the paint raw materials towards the barrel wall during rotation, and then rebounds back from the barrel wall to the agitator. This repeated cycle creates strong convection and shear effects on the paint raw materials in the mixing barrel, achieving uniform mixing. When the mixing reaches the preset uniformity, the control system turns off the motor, opens the discharge port, and discharges the evenly mixed coating.

Company profile

Jiangmen Homemaster Electric Motors and Appliances Manufacturing Company Limited

Recommended products