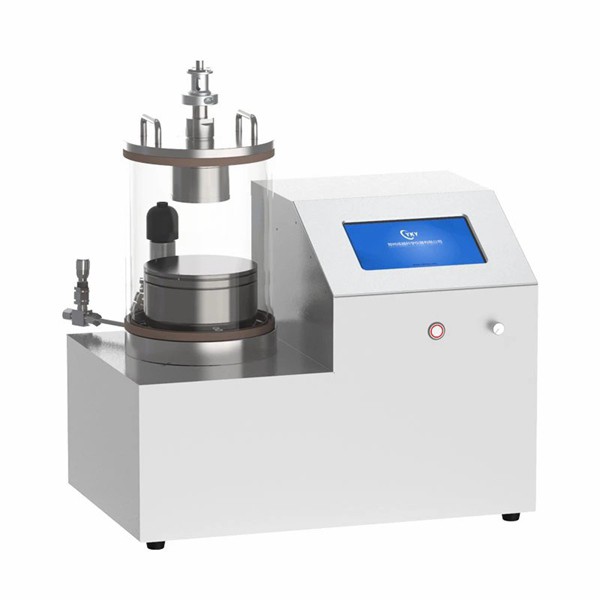

High Quality Small 150W DC Power Supply Magnetron Sputter Coater

Product description

The basic components include a vacuum system, sedimentation chamber, power supply, and control system. The vacuum system is used to create a vacuum, and the deposition chamber is the main area for depositing thin films. The power supply controls parameters such as material deposition speed and temperature, and the control system ensures that the deposition thickness, uniformity, and quality of the thin film meet the requirements. According to different processes, requirements, and applications, coating machines can be divided into various types, such as physical vapor coating machines, chemical vapor coating machines, ion coating machines, magnetron coating machines, sputtering coating machines, etc.

With the continuous development of materials science, vacuum technology, electronic technology and other fields, sputtering coating technology is also constantly innovating and improving. In the future, sputtering coating machines will pay more attention to technological innovation in improving coating quality, reducing production costs, and improving production efficiency. With the continuous development and improvement of sputtering coating technology, its application fields will also continue to expand. In the future, sputtering coating machines will be more widely used in emerging fields such as new energy, environmental protection, and biomedicine, providing strong support for the development of these fields.

Recommended products