Wholesale Price Flexible Metal Conduit Hose PVC Jacket

Product description

The size and specifications of cable conduits must comply with design requirements and relevant standards. The test includes the diameter, length, wall thickness, bending radius, etc. of the catheter. Use a bending tester or bending block for testing to simulate the bending of cable conduits in actual use. Bend the conduit within the specified bending radius and observe whether there are any cracks, indentations, or other deformations on its surface, in order to determine whether its flatness meets the standard requirements. For cable conduit joints, sealing tests are required to ensure they do not leak. The testing methods include hydrostatic testing and pneumatic testing, which observe the sealing performance of the joint by applying a certain amount of pressure.

With the advancement of technology and the improvement of environmental awareness, the development of cable conduits is moving towards environmental protection, energy conservation, intelligence, and other directions. In the future, cable conduits will pay more attention to the application of environmentally friendly materials and the research and development of energy-saving and emission reduction technologies to meet society's demand for green energy. Meanwhile, with the continuous development of technologies such as the Internet of Things and big data, cable conduits will gradually achieve intelligent management, improving the automation level and operational efficiency of power transmission systems.

Cable conduits are widely used in fields such as power, communication, petroleum, and chemical engineering. In the field of power, cable conduits are mainly used to protect power cables and ensure the stability and safety of power transmission; In the field of communication, cable conduits are used to protect communication cables and ensure the smooth flow of communication signals; In the fields of petroleum and chemical engineering, cable conduits are used to protect cables in oil and gas pipelines, ensuring smooth oil and gas transportation.

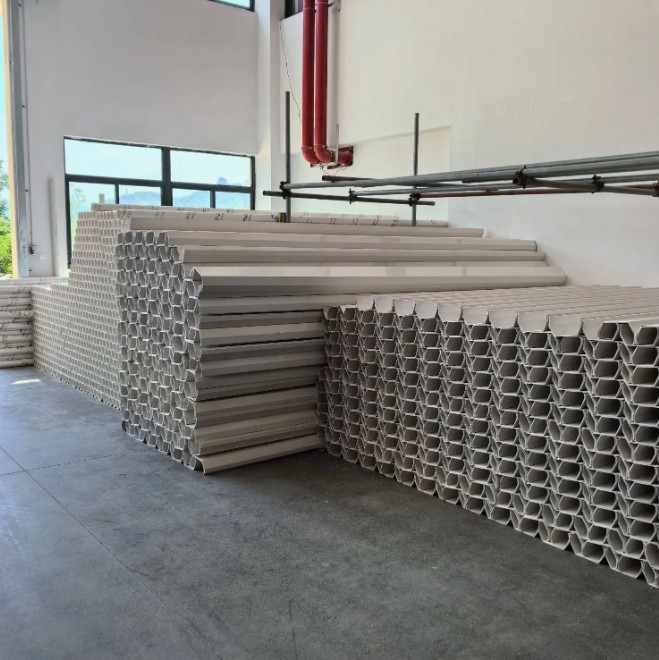

Some cable conduits are made of flame-retardant materials, which have good fire resistance and can effectively prevent the spread of fire in the event of a fire, protecting the cables from damage. The design of cable conduits has a certain degree of flexibility, can adapt to the installation needs of different terrains and environments, and is convenient for construction and maintenance. The cable conduit is made of high-strength materials, which have a long service life and good durability, and can operate stably for a long time in harsh environments.

Cable conduits can effectively protect cables from external environmental damage, such as natural factors such as rain, wind and sand, ultraviolet radiation, as well as accidental damage such as human damage and animal bites. Cable conduits can isolate cables from the external environment, prevent them from electromagnetic interference and pollution, and ensure the stability and safety of power transmission.

Recommended products