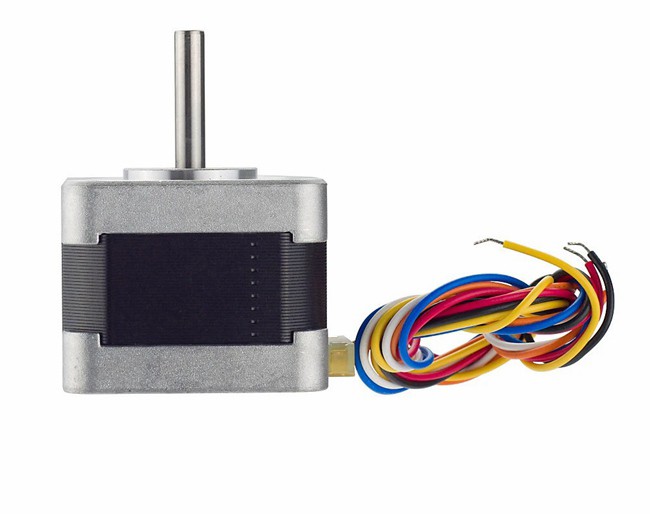

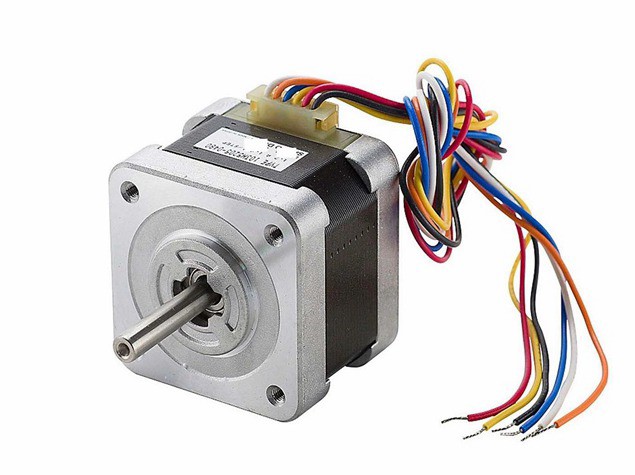

High Torque Stepper Motors for Industry Use Standard Stepper Motor with ISO and CE

Product description

The working principle of a reactive stepper motor is relatively simple, with many small teeth evenly distributed on the rotor. The stator teeth have three excitation winding resistances, and their geometric axes are sequentially offset from the rotor tooth axis. The position and speed of the motor correspond one-to-one with the number of conductive pulses and frequency. The direction is determined by the order of conductivity. Generally, reactive stepper machines with two, three, four, and five phases are predominant in the market.

Although there are still certain differences between stepper motors and imported stepper motors in certain aspects, such as high-speed torque, accuracy, etc., these differences can be ignored in most cases. Especially in terms of price, stepper motors have significant advantages, making them more competitive in the domestic market. In addition, with the continuous progress of technology and the improvement of quality, the performance of stepper motors is gradually approaching or even surpassing international brands.

With the transformation and upgrading of the manufacturing industry and the promotion of intelligent manufacturing, the size of the Chinese stepper motor market is expected to grow at a rate higher than the global average. At present, the domestic stepper motor market is mainly occupied by domestic manufacturers and overseas enterprises, with a domestic market share of over 50%. In the domestic market, some enterprises such as Northern Electric, Mechanical and Electrical Port, and Shanghai Electric occupy a dominant position.

Through reasonable design and material selection, stepper motors can provide sufficient torque to cope with various load situations, whether it is low-speed high torque operation or high-speed low torque operation, and can maintain stable output. Compared to other types of motors, stepper motors have lower working sound and lower vibration, making them very important for certain applications that require high environmental noise and vibration, such as medical equipment and precision instruments. The stepper motor has a simple structure, is easy to maintain, and adopts advanced manufacturing technology, which can operate normally in various harsh environments and has strong durability.

The stepper motor can precisely control the position and speed by controlling the number and frequency of pulses, meeting the requirements of high-precision application scenarios. The operation of the stepper motor is completely controlled by pulse signals, with strong programmability and easy implementation of complex control strategies. The stepper motor consists of three parts: the motor itself, the driver, and the controller, making installation and maintenance relatively easy. At low speeds, stepper motors have high torque output and are suitable for applications that require high torque.

Recommended products