Steel wire size chart

Product description

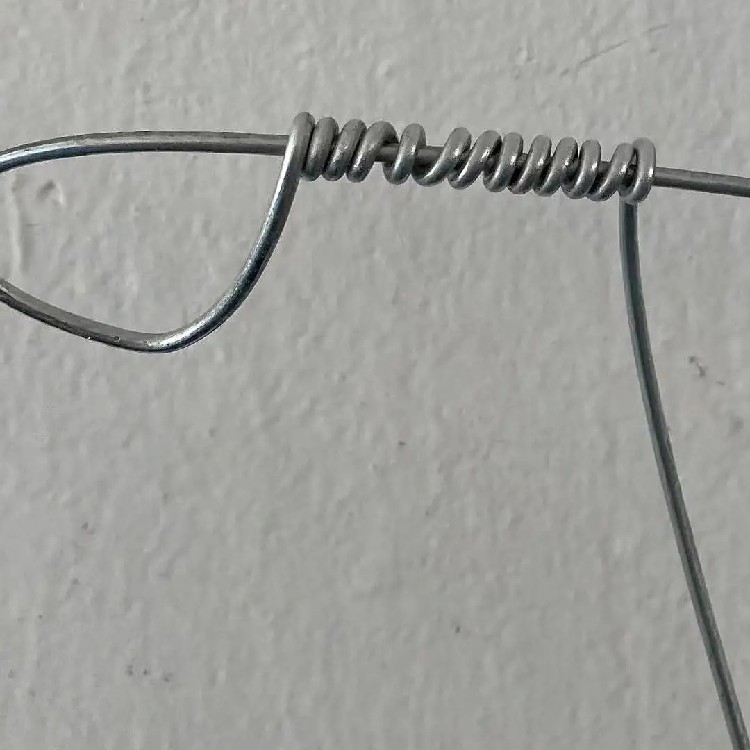

Galvanized steel wire is a steel wire product with the advantages of corrosion resistance, wear resistance, and high tensile strength. It is widely used in construction, transportation, agriculture and other fields. There are many different sizes of galvanized steel wire on the market, each with its specific uses and characteristics. Galvanized steel wire, as an indispensable and important material in modern industry and construction fields, comes in various models, each of which is carefully designed for different application requirements and engineering standards.

The selection of galvanized steel wire models is very important and directly affects the performance and quality of the product. High-quality raw materials ensure the anti-corrosion performance and service life of galvanized steel wire. Usually, high-quality steel is selected as the raw material. After a series of refining and processing, a uniform and dense coating is formed in the galvanizing process, which improves the corrosion resistance and strength of steel wire and meets the needs of different fields.

Galvanized steel wire has many innovations and breakthroughs in technology. The use of advanced production equipment and processes ensures product quality stability and consistency. Through the combined application of different processes, zinc coating on the surface of steel wire is made more uniform and smooth, the hardness and wear resistance of the metal surface are improved, and the service life is extended.

Steel wire size chart:

In GB/T3428, the diameter range of galvanized steel wire is 1.24mm-5.5mm, range of zinc layer is: Class A and Class B (185g/m2-580g/m2), and tensile strength grades are: ordinary strength ( Grade A zinc layer has a minimum tensile strength of 1290Mpa, corresponding to a minimum stress of 1100Mpa at 1% elongation; Grade B zinc layer has a minimum tensile strength of 1190Mpa, corresponding to a minimum stress of 1000Mpa at 1% elongation), high strength ( Grade A zinc layer has a minimum tensile strength of 1380Mpa, corresponding to a minimum stress of 1170Mpa at 1% elongation; Grade B zinc layer has a minimum tensile strength of 1280Mpa, corresponding to a minimum stress of 1100Mpa at 1% elongation), ultimate high strength (Grade A zinc layer, minimum tensile strength is 1500Mpa, corresponding to minimum stress at 1% elongation is 1270Mpa)

In YB/T5294, galvanized steel wire size numbers gauge from 3 to 36, corresponding to SWGBWGAWG respectively. The wire gauge numbers our company can produce are 3-20.

In BS EN 50189, galvanized steel wire diameter gauge: 1.24mm-5.5mm, zinc coating requirement range: class A, class B, class C, class D, class E (185g/m2-825g/m2), tensile strength strength level: ST1A, ST2B, ST3D, ST4A, ST5E, ST6C.

In ASTM B498, galvanized steel wire diameter range: 1.6mm-4.8mm, zinc coating requirement range: class A, class B, class C (210g/m2-900g/m2), tensile strength range: 1240-1450Mpa, The minimum stress value corresponding to 1% elongation: 1070-1310Mpa.

If you want to know more details or product requirements, please contact our company in time.

Recommended products