Processing and customizing special-shaped temperature balancing plates

Product description

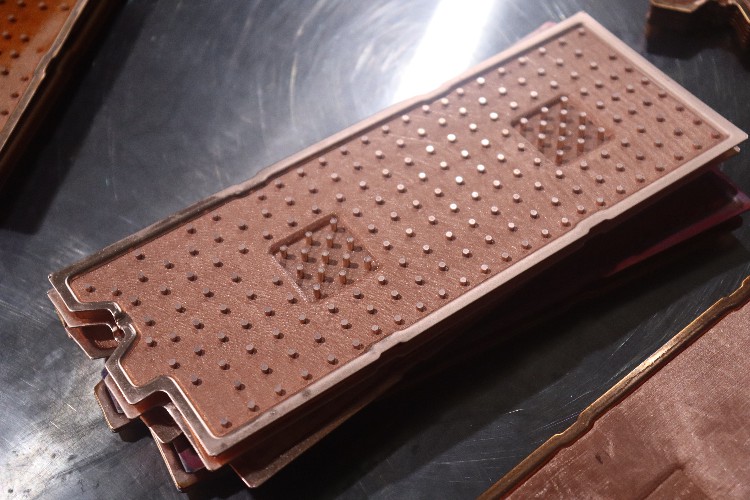

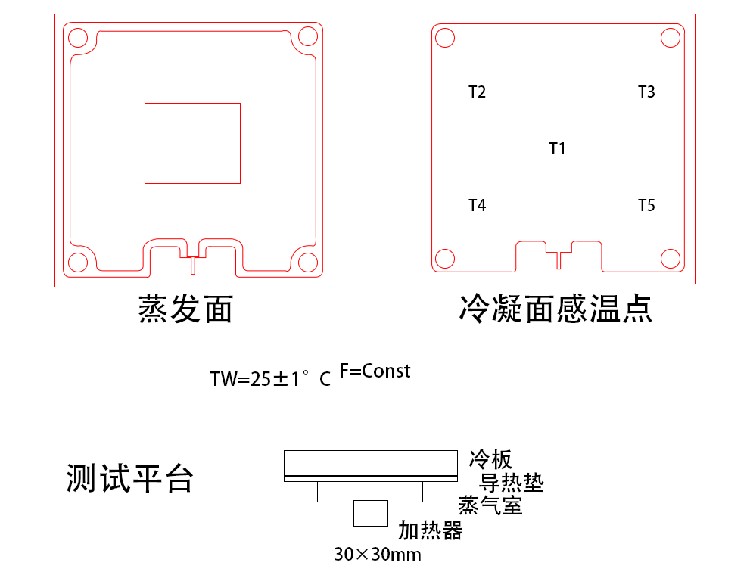

Processing of customized special-shaped vapor chambers

Our company can process and customize various vapor chambers:

Capillary liquid absorbent core structure: tungsten copper powder, tungsten copper wire mesh;

Welding process: copper paste welding, diffusion welding;

Maximum size: 500*320mm;

Maximum power: 1500W;

Able to design and manufacture copper/water room temperature vapor chambers and copper/methanol low temperature vapor chambers

VC capillary structure and thickness

vapor chamber thickness

Capillary structure>=1.6mm

Rainbow copper powder+copper powder ring+copper pillar>=0.4mm

Tungsten copper wire mesh + copper powder column <=0.8mm

Sintered special copper powder <=0.8mm

Fluctuating copper wire mesh + fluctuating special copper powder

VC welding process

Welding manufacturing process characteristics application industries

Diffusion lasts for 15 years; cost is high; fixture cost is high communication/database/server,

Copper solder paste has a welding life of 10 years; low cost; low fixture cost computer/mobile phone/electronic consumption

Different working fluids and temperature ranges

Container/working fluid Working temperature range Age temperature

Copper/Water +30°C ~ +120°C +135°C

Copper/Methanol 40°C ~ +90°C +100°C

Vapor chamber maximum size and power reference table

Thickness (mm) Maximum length (mm) Maximum width (mm) Maximum thermal power (W)

3.0=<T<= 10 500 320 500W ~ 1500W

1.6-<T<3 320 150 130W ~ 500W

0.5=<T<=1.5 200 100 13W~ 130W

0.2-<T<=0.4 120 60 3W~8W

Recommended products