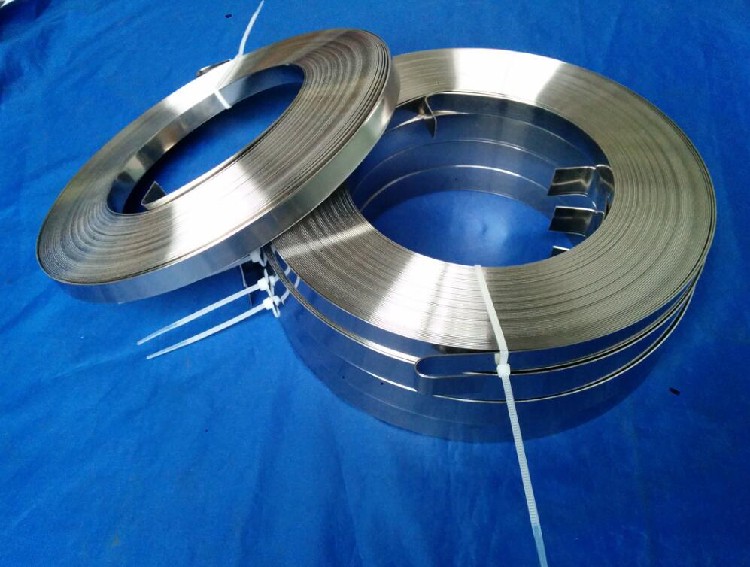

5mm stainless steel hot rolled strip price

Product description

Hot-rolled strip steel refers to strips and plates produced by hot rolling. The general thickness is 1.2 to 8 mm. Strip steel with a width of less than 600 mm is called narrow strip steel, and strip steel with a width of more than 600 mm is called wide strip steel.

5mm stainless steel hot rolled strip price

The price of hot-rolled strip steel is 3270.00 yuan/ton.

The price of hot-rolled strip steel is shown as 3270.00 yuan/ton in the latest data. This price is based on the data on August 27, 2024, indicating that the price of hot-rolled strip steel has changed in the near future. As an important building material, the price changes of hot-rolled strip steel may be affected by various factors such as market demand, supply conditions and international raw material prices. Therefore, it is very important for relevant companies and individuals who are concerned about the price changes of hot-rolled strip steel to obtain the latest price information in a timely manner.

Product Features

The plate and strip products are flat in shape, with a large width-to-thickness ratio and a large surface area per unit volume. This appearance feature brings the following characteristics to their use:

(1) The large surface area makes it have a strong covering capacity and is widely used in chemical industry, containers, construction, metal products, metal structures, etc.

(2) It can be cut, bent, stamped, welded, and made into various product components at will. It is flexible and convenient to use and occupies an extremely important position in the automotive, aviation, shipbuilding and automobile manufacturing sectors.

(3) It can be bent and welded into various complex cross-section steel, steel pipes, large I-beams, channel steel and other structural parts, so it is called "universal steel".

Technical parameters of hot-rolled steel strip

In addition to specifications, the technical parameters of hot-rolled steel strip are also the key to selection. The commonly used technical parameters of hot-rolled steel strip are as follows:

1. Thickness: The thickness of hot-rolled steel strip usually ranges from 1.2mm to 25.0mm.

2. Width: The width of hot-rolled steel strip usually ranges from 1000mm to 1800mm.

3. Strength grade: The strength grade of hot-rolled steel strip is usually divided into different grades such as Q195, Q215, Q235, Q345, ST37-2, ST52-3, etc.

Types

Depending on the processing method and purpose, hot-rolled steel strips can be divided into many different types, including:

1. General-purpose hot-rolled steel strips: mainly refers to hot-rolled steel strips in cold-rolled plates, railway vehicle manufacturing, automobile manufacturing, shipbuilding, building structures and other fields.

2. High-strength hot-rolled steel strips: The strength requirements of the steel strips are relatively high, and they are suitable for components and parts that require large loads.

3. Ship plate hot-rolled steel strips: Suitable for use in shipbuilding, usually requiring good weldability and cold bending performance.

4. Oil and gas pipeline hot-rolled steel strips: Mainly used in oil and gas pipelines and other fields, requiring the steel strips to have high wear resistance and corrosion resistance.

5. Advanced automotive steel hot-rolled steel strips: Suitable for automotive mesh plates and other fields, requiring the steel strips to have high strength, good formability and welding performance.

In short, different types of hot-rolled steel strips have different properties and uses, and the selection should be carefully considered according to specific needs.

The technical requirements for hot-rolled strip mainly include four aspects, namely, dimensional accuracy, plate shape, surface quality and performance.

(1) High dimensional accuracy requirements. Dimensional accuracy mainly refers to thickness accuracy, because it not only affects the performance and the subsequent process of continuous automatic stamping, but also has the greatest control difficulty in production. In addition, thickness deviation has a great impact on metal saving.

(2) The plate shape should be good. The plate shape should be flat and free of waves and bends to be good for use. However, since plates and strips are both wide and thin, they are particularly sensitive to uneven deformation, so it is not easy to maintain a good plate shape. The thinner the plate and strip, the greater its sensitivity to uneven deformation, and the more difficult it is to maintain a good plate shape. Obviously, the poor plate shape comes from uneven deformation, and uneven deformation often leads to uneven thickness. Therefore, the quality of the plate shape is often directly related to the thickness accuracy.

(3) The surface quality should be good. Plates and strips are the steel with the largest surface area per unit volume, and are mostly used as peripheral components, so the surface quality must be guaranteed. Surface defects not only damage the appearance of plate parts, but also often deteriorate the performance or become the source of cracks and rust, and become a weak link for stress concentration.

(4) Good performance. The performance requirements of plates and strips mainly include mechanical properties, process properties and special physical or chemical properties of certain steel plates. General structural steel plates are only required to have good process properties, such as cold bending and welding properties, and the requirements for mechanical properties are not very strict.

Recommended products