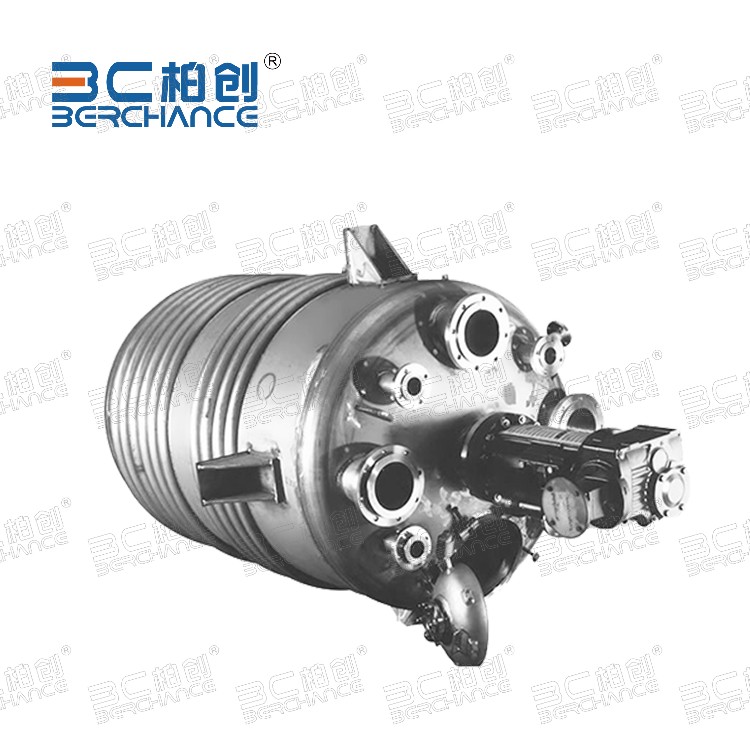

China Suppliers Distillation Using High Pressure Column Reaction Kettle

Product description

The working principle of a distillation kettle is based on the principle of phase change in physics, which means that a liquid will transform into steam when it reaches its boiling point, and different liquids have different vapor pressures at the same temperature. Therefore, low boiling point components in the mixture can be vaporized first by heating, and then condensed into liquid by a condenser to achieve component separation. In this process, the design and operation of the distillation kettle, as a place for reaction and separation, are crucial for the separation effect.

Reaction vessels are widely used in industries such as petroleum, chemical, rubber, pesticides, dyes, pharmaceuticals, and food. In these industries, reaction vessels are used to complete processes such as sulfurization, nitration, hydrogenation, alkylation, polymerization, and condensation. For example, in the pharmaceutical industry, reaction vessels are used as critical steps in drug synthesis processes; In the chemical industry, it is used for the synthesis and purification of various chemicals.

The distillation kettle has the advantages of simple structure, convenient operation, and good separation effect. Meanwhile, with the continuous advancement of technology, modern distillation kettles have also achieved higher levels of automation and a wider range of applications. In order to solve the problem of intermittent maintenance and cleaning of solid and high boiling point substances in the production process of traditional distillation kettles, modern distillation kettles have made many improvements in design, such as adding devices such as demisters and settling chambers, to improve production efficiency and product quality.

In the vast field of chemical industry, distillation kettle plays an indispensable role as a key separation equipment. It utilizes the difference in boiling points of each component in the mixture to achieve effective separation of components through processes such as heating, vaporization, and condensation, providing important technical support for chemical production. The main function of a distillation kettle is to vaporize the distilled liquid and provide the necessary amount of rising steam in the tower to achieve effective separation of components. Widely used in pharmaceutical, chemical, food, light industry and other fields. In the pharmaceutical industry, distillation kettles are commonly used to extract active ingredients from drugs; In the chemical industry, it is used for the purification and separation of various chemicals.

Distillation kettle is a widely used equipment in chemical production, mainly used to separate liquid mixtures into different components by distillation. A distillation kettle is a specialized equipment used for distillation in chemical production, which separates the components of a liquid mixture according to their boiling points by heating. Based on the difference in boiling points of each component in a liquid mixture, the low boiling components are first vaporized by heating, and then condensed into liquid by a condenser to achieve component separation.

Recommended products