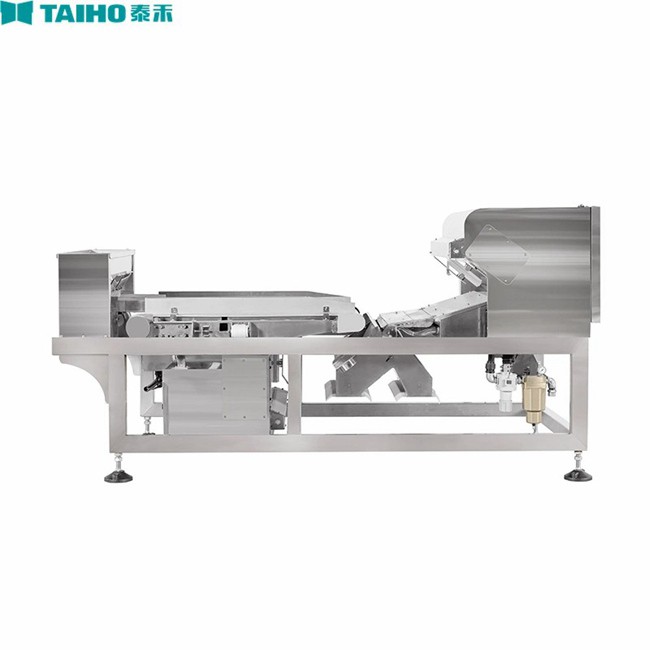

High Quality Bean color sorter, peanut and mung bean color sorter

Product description

Color sorter is a device that uses photoelectric detection technology to automatically sort out particles of different colors or other materials that do not meet the standards in granular materials based on the differences in optical properties of materials. By identifying small differences in color, shape, size, and other aspects of materials, defective products, impurities, or materials that do not meet specific standards can be separated, thereby improving the overall quality and market competitiveness of the product. It has a wide range of applications in various fields such as food processing, agricultural product processing, mining, and chemical engineering.

In addition to the basic color selection function, some high-end grain color selection machines also have multiple functions such as stone removal, impurity removal, and grading, which can meet the needs of different users. Grain color sorter usually adopts a full-color touch screen operation interface with user-friendly design, making the operation more convenient and easy to learn.

The grain color sorter adopts a high-resolution CCD image sensor and a professional image processing system, which can accurately identify small color differences in grains. The color sorting accuracy can usually reach over 99.9%. Combined with high-frequency solenoid valves and other actuators, the grain color sorter can achieve high-speed and continuous sorting operations, with a large processing capacity and high efficiency.

Grain color sorter is a machine specifically designed for grain sorting. It utilizes advanced image recognition technology and optoelectronic technology to quickly and accurately identify and separate out discolored grains, moldy grains, impurities, etc. in grains, thereby improving the quality and added value of grains.

Food color sorter has a wide range of applications in multiple fields, including but not limited to:

Grain processing: such as rice, wheat, corn, etc., color sorting machines can effectively remove discolored grains, diseased grains, insect eaten grains, etc.

Fruit and vegetable processing: During the processing of fruits and vegetables, color sorting machines can remove defects such as insect holes, rotten fruits, and decay, improving the quality and appearance of the products.

Nuts and dried fruits: The color sorter can remove impurities, insect shells, mold, etc. from nuts and dried fruits, improving product quality.

Seafood: Used to remove impurities, shells, spines, etc. from seafood, and improve the hygiene and safety of products.

Recommended products