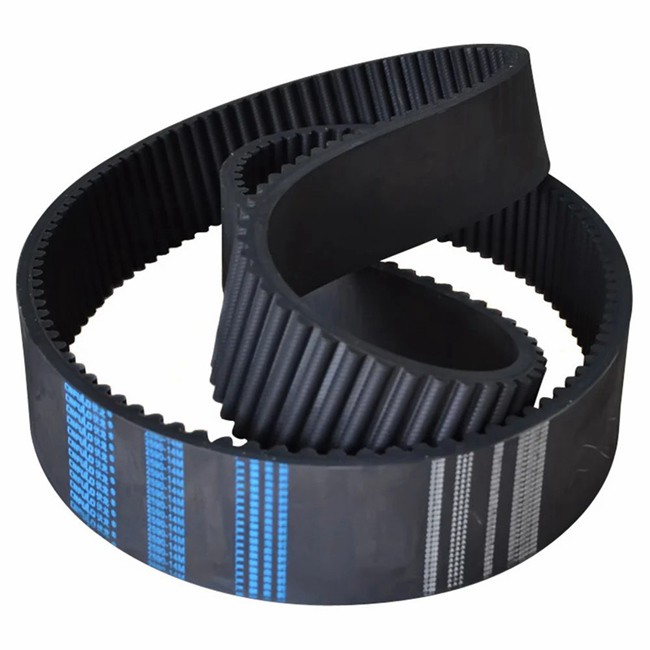

Customized Rubber Industrial Timing Belt Htd Std

Product description

Synchronous belts are widely used in various fields such as automotive industry, industrial machinery, electronic equipment, automation equipment, food processing machinery, packaging equipment, etc. They achieve speed synchronization through precise tooth profile design, and have advantages such as high efficiency, precision, load bearing capacity, and low noise, providing important support for the development of modern mechanical transmission systems.

Product Features

High efficiency: The transmission efficiency of synchronous belts is relatively high, usually reaching over 98%, far higher than traditional belt transmission.

Accuracy: Due to the close fit between teeth and grooves, synchronous belts can ensure the accuracy of transmission and reduce errors.

Wear resistance: Synchronous belts are usually made of rubber and reinforced materials, which have good wear resistance and can extend their service life.

Low noise: The toothed design of the synchronous belt helps reduce noise during transmission and improve the comfort of the working environment.

High load capacity: Some synchronous belts are embedded with tensile materials such as steel wires or Kevlar cables, which can withstand high loads.

Rubber synchronous belts play a crucial role in automotive engines, used to drive auxiliary equipment such as generators, water pumps, and air conditioning compressors, ensuring accurate synchronization between the engine's valves and pistons. In industrial machinery such as high-speed packaging machines, printing equipment, and paper making machinery, rubber synchronous belts are used for transmission and positioning to ensure production efficiency and product quality.

Due to the use of high-quality rubber materials and reasonable design, rubber synchronous belts have good dynamic bending performance and can adapt to various complex transmission environments. Through precise tooth meshing, rubber synchronous belts can achieve efficient transmission and reduce energy loss. Rubber synchronous belt can ensure the accuracy of transmission ratio and meet the requirements of high motion accuracy in situations. Rubber synchronous belts usually have good oil and high temperature resistance, and can work stably in harsh working environments.

Recommended products