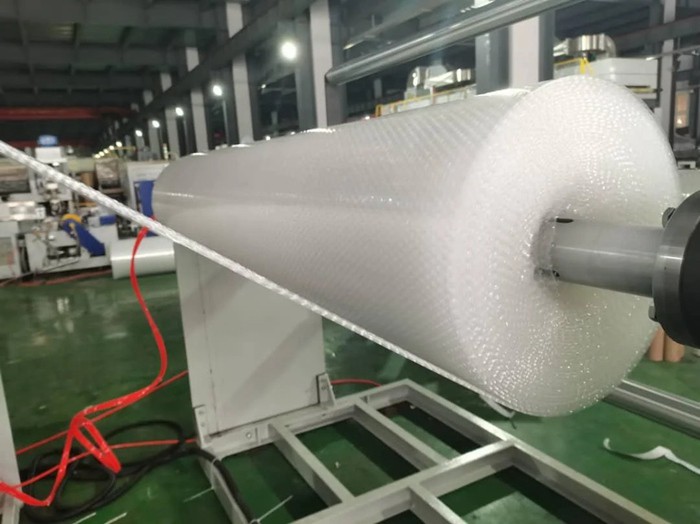

High Speed Filmplastic Bubble Film Machine for Aluminum Laminating Machine

Product description

According to the manufacturing method and the method of generating bubbles, bubble wrap machines can be divided into various types, such as manual bubble wrap machines, extrusion bubble wrap machines, and stamping bubble wrap machines.

Manual bubble film machine: requires manual up and down operation, with low production efficiency, but easy to operate, suitable for individuals or small manufacturers to produce low specification bubble films.

Extrusion type bubble film machine: It uses extrusion and stretching methods to produce bubble film, with fast speed and high production efficiency. It is suitable for producing bubble films with large thickness and specifications.

Stamping type bubble film machine: using mold stamping to form bubble film, suitable for producing bubble films of various specifications and shapes.

Working principle: Different types of bubble film machines have different working principles, but overall they process polyethylene and other raw materials into thin films with bubble structures through specific processes.

Extrusion bubble film machine is a specialized equipment that uses extrusion and stretching methods to produce bubble film. The core part of the machine is the extruder, which deforms polymer materials (such as polyethylene) by squeezing them to produce the raw material for bubble wrap. The extruder consists of a melting system, a filtering system, an extrusion system, and a regulating system. The melting system heats and melts plastic particles, the filtering system removes impurities and defective materials, the extrusion system applies pressure to the molten material, and the regulating system controls parameters such as temperature, pressure, and speed. The melted polymer material is then fed into the bubble mold through a nozzle for bubble forming operation.

Recommended products