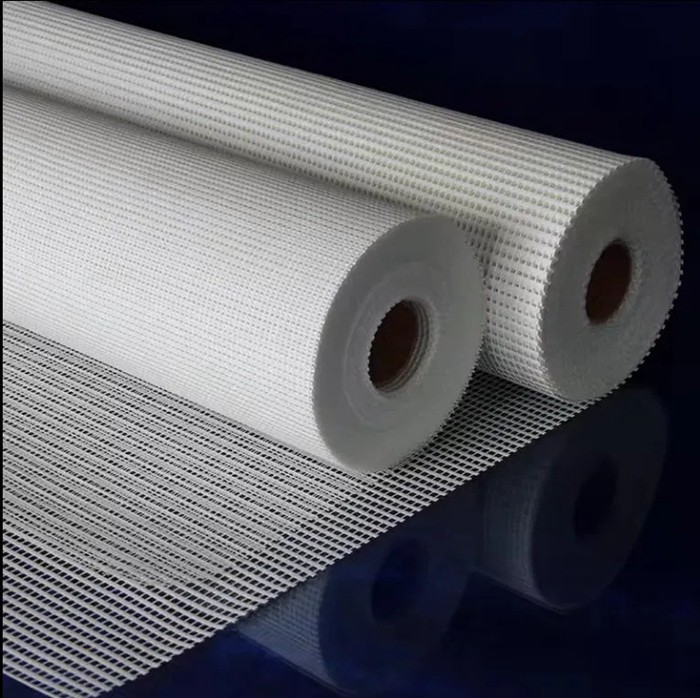

Fiberglass Mesh Fabric: The Essential Reinforcement Solution

Product description

Fiberglass mesh fabric is an open-weave textile manufactured from continuous glass fiber strands. These strands are typically coated with specialized materials—most commonly alkali-resistant (AR) compounds for construction applications or PVC for industrial uses to enhance durability and performance. Characterized by its grid-like structure, this material offers exceptional tensile strength while maintaining remarkable flexibility. Available in various densities (mesh counts), weights (measured in GSM - grams per square meter), and roll sizes, it provides versatile reinforcement across multiple industries.

Primary Applications

Building Facades: Integral to Exterior Insulation and Finish Systems (EIFS) and synthetic stucco, preventing crack propagation in wall systems.

Wall & Ceiling Reinforcement: Embedded in cement plaster, gypsum plaster, and tile adhesives to control cracking in concrete, masonry, and drywall surfaces.

Flooring Systems: Reinforce self-leveling compounds, screeds, and waterproofing membranes for floors and balconies.

Waterproofing & Roofing: Serve as a critical reinforcing layer in liquid-applied waterproofing membranes and roof coatings.

Pipe & Tank Protection: Reinforce anti-corrosion coatings for pipelines and storage tanks.

Repair & Renovation: Used for mending cracks in concrete, plaster, and drywall.

Industrial Uses: Function as a reinforcement in composite materials, filtration media, and insulation backing.

Key Advantages

Superior Tensile Strength: Effectively distribute stress and resist cracking under tension.

Lightweight & Flexible: Easy to transport, cut, and conform to curved or irregular substrates.

Corrosion Resistance: Unlike metal alternatives, it will not rust or corrode, ensuring long-term structural integrity.

Alkali Resistance (AR Coated): Withstand the highly alkaline environment of cementitious products without degradation.

Dimensional Stability: Resist shrinking, stretching, or warping under normal conditions.

Chemical Resilience: Exhibit excellent resistance to most chemicals found in construction and industrial settings.

Fire Safety: The glass fiber core is non-combustible (inorganic), contributing to fire-resistant assemblies.

Thermal Compatibility: Low thermal expansion coefficient minimizes stress under temperature fluctuations.

Ease of Installation: Simple to embed into wet mortars, adhesives, or coatings using standard tools.

Fiberglass Mesh Fabric: Key Questions Answered

Q1: Why is alkali-resistant (AR) coating essential for construction applications?

A1: Fresh cement, plaster, and grout create a highly alkaline environment during curing. Standard fiberglass can deteriorate under these conditions. AR coating forms a protective barrier, ensuring that the mesh maintains its reinforcing strength throughout the lifespan of the structure.

Q2: Can this mesh be used effectively for exterior projects?

A2: Yes, alkali-resistant fiberglass mesh is specifically engineered for exterior use. It performs reliably in EIFS, stucco systems, and exterior renders, enduring weathering, UV exposure (when properly embedded or top-coated), and temperature variations.

Q3: How does fiberglass mesh compare to traditional steel reinforcement mesh (e.g., chicken wire)?

A3: Fiberglass mesh offers significant advantages: it is much lighter and easier to handle, inherently corrosion-proof, and provides superior crack control for thin-layer applications like renders and tile adhesives. Steel mesh requires galvanization for corrosion resistance and is heavier and less flexible.

Q4: What weight (GSM) and mesh size should be chosen for different jobs?

A4: Selection depends on the application:

Light-duty repairs (drywall cracks): 60-90 GSM.

Standard wall rendering/tiling: 110-145 GSM (common for AR mesh).

Heavy-duty rendering/EIFS base coats: 160-300+ GSM.

Mesh size: Finer meshes (e.g., 4x4mm, 5x5mm) are standard for renders and plasters; larger meshes might be used in specific composites or industrial contexts.

Q5: How should mesh seams and overlaps be handled during installation?

A5: Proper overlapping is crucial for continuous reinforcement. Typically, adjacent rolls should overlap by a minimum of 50-100mm (2-4 inches). Ensure that the mesh is fully embedded in the wet adhesive, plaster, or coating without wrinkles or air pockets. Avoid overlapping at corners where stress concentrates; instead, use single pieces bent around corners.

Recommended products