Resource Utilization of Steel Plan Dust-High-Efficiency Rotary Kiln Solution Industry Pain Points

Product description

Industry Pain Points

Steel production generates dust containing valuable elements like iron, carbon, and zinc. Direct stockpiling or landfilling not only wastes resources but also risks environmental pollution. Achieving safe disposal, resource recovery, and high-efficiency recycling remains an industry challenge.

Core Advantages of Rotary Kiln Dust Treatment

High-Efficiency Resource Recovery

High-temperature roasting (1200-1400°C) separates iron, zinc, and other metals.

Iron is recycled into sintering processes.

Zinc is concentrated for smelting, turning waste into treasure.

Carbon combustion reduces fuel costs.

Eco-Compliance

Equipped with flue gas purification (dust removal + desulfurization/denitrification), meeting national/EU standards for dioxins and heavy metals.

Slag is treated harmlessly, eliminating secondary pollution.

Economic Benefits

Reduces raw material costs (iron/zinc recovery rate >90%).

Processes high-zinc dust (ZnO ≤15%), solving utilization challenges.

Proven & Reliable Technology

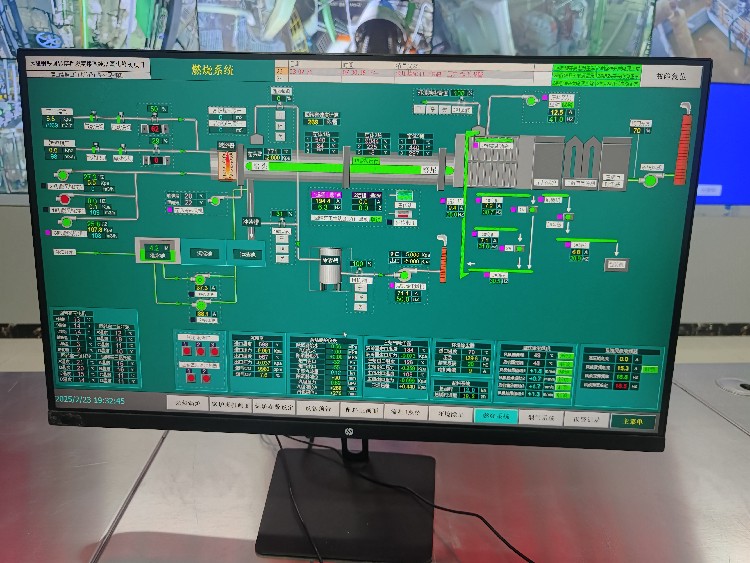

Widely adopted in metallurgical waste treatment, with long equipment lifespan, high automation, and easy maintenance.

Process Overview

Pre-Treatment: Pelletizing/briquetting dust for uniform kiln feeding.

Roasting & Reduction: High-temperature reduction in the rotary kiln volatilizes zinc (captured in flue gas) and reduces iron to metal particles.

Flue Gas Treatment: Zinc oxide is collected via cooling/bag filters; purified emissions meet standards.

Product Utilization:

Iron → Recycled to steelmaking/sintering

Zinc-rich dust → Sold to zinc smelters

Residual slag → Construction materials

Why Choose Our Rotary Kiln Solution?

✅ Custom Design: Optimized parameters based on dust composition (Fe/Zn/C content).

✅ Energy Efficiency: Waste heat recovery cuts operational costs.

✅ EPC Service: Full-chain support from design to operation.

Recommended products