SUS304 Perforated Mesh Cylinder Tube

Product description

How it works

1.Flow Direction: The fluid (containing solid particles) flows from the outside-in or inside-out of the filter tube.

2.Filtration: As the fluid passes through the perforated holes in the tube wall, particles larger than the hole size are retained on the surface of the filter tube.

3.Separation: The cleaned fluid passes through the tube wall and continues its journey through the system.

Manufacturing methods;

1,Punching: Mechanical or laser punching for precision holes.

2,Expanded Metal: Stretching metal to create mesh-like perforations.

3,Wire Mesh Wrapped: Perforated core wrapped with Woven Wire Mesh for enhanced filtration.

Features

• High porosity and excellent permeability.

• Corrosion resistance and high temperature resistance.

• Large dirt-holding capacity.

• Accurate filtration precision.

• Easy processing and installing.

• Easy forming, painting, polishing, welding and cleaning.

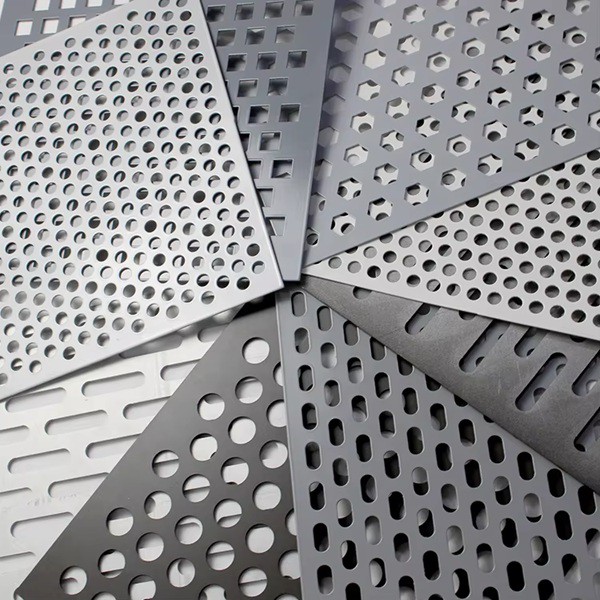

• Firm structure and different hole patterns.

Recommended products