hast high-pressure accelerated aging test chamber

Product description

A HAST (Highly Accelerated Stress Test) High-Pressure Accelerated Aging Test Chamber is a specialized environmental test chamber used to simulate the long-term effects of high temperature, high humidity, and elevated pressure on materials or electronic components in a relatively short period. This test chamber is commonly used in industries such as electronics, automotive, aerospace, and manufacturing to accelerate the aging process of materials, devices, or components.

Key Features of a HAST High-Pressure Accelerated Aging Test Chamber:

- High-Temperature and High-Humidity Control:Temperature Range: Typically from +85°C to +200°C or higher, depending on the machine's specification.Humidity Range: HAST chambers can achieve relative humidity (RH) levels from 85% RH to 98% RH. This high humidity accelerates the degradation process of materials and simulates the effects of environmental exposure.Controlled Atmosphere: The chamber maintains high pressure to simulate extreme environmental conditions that would be encountered in real-life applications.

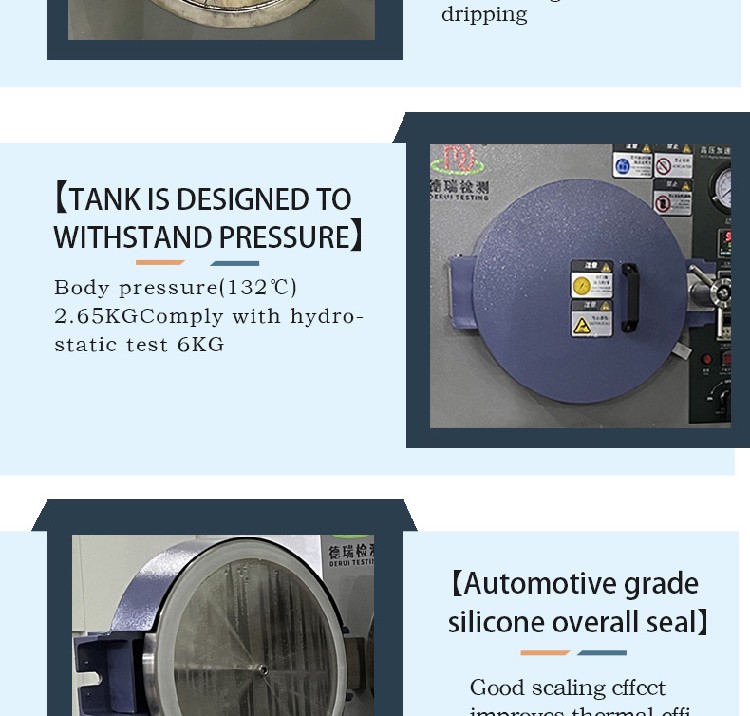

- High-Pressure System:Pressure Control: The chamber can create and maintain high pressure, typically up to 2-3 bars (200-300 kPa) or more, to accelerate the aging process.Pressure Cycling: Some HAST chambers can also perform pressure cycling, which subjects the sample to rapid pressure variations to simulate conditions such as those encountered during transportation, handling, or exposure to changing altitudes.Pressure-Resistant Chamber: The inner chamber is constructed to withstand the required high pressure, and it is equipped with safety features such as pressure relief valves to ensure safe operation.

- Accelerated Aging Simulation:Time Compression: The goal of the HAST chamber is to simulate several years of environmental exposure within a matter of days or weeks. The combination of high temperature, humidity, and pressure accelerates the degradation of materials or components.Real-Time Monitoring: The chamber typically comes with sensors and a real-time data acquisition system to monitor temperature, humidity, pressure, and other test parameters continuously.Test Duration: Tests can range from a few hours to several days depending on the type of material or component being tested and the aging conditions defined.

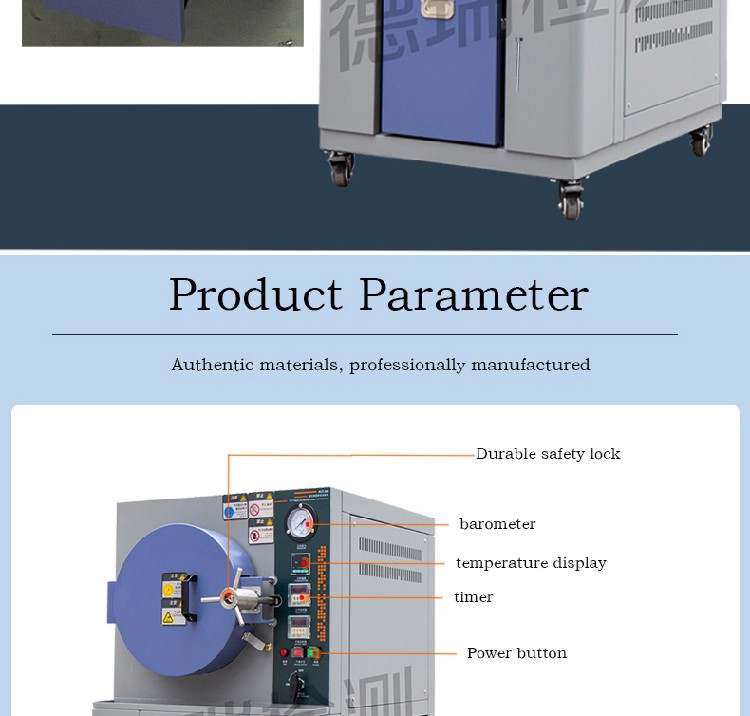

- Automated Testing and Controls:Touchscreen Interface: Modern HAST chambers often come with a touchscreen interface that allows for easy setup, monitoring, and modification of test parameters such as temperature, humidity, and pressure.Programmable Test Profiles: Users can program custom temperature, humidity, and pressure profiles with ramp rates and dwell times. This allows for precise simulation of specific environmental conditions.Data Logging and Reporting: Built-in data logging and reporting software track critical parameters and generate detailed reports on test results.

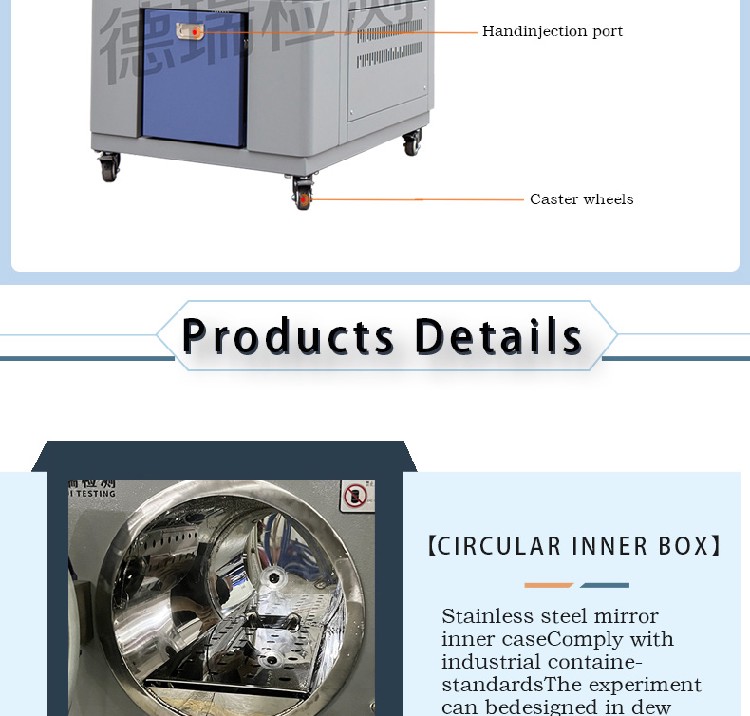

- Sample Loading and Handling:Sample Capacity: The chamber is equipped with racks or trays to hold multiple samples during the test.Temperature Uniformity: Uniform temperature distribution is essential to ensure consistent aging effects across all test samples.Accessibility: Some models come with easy-access ports for loading and unloading samples without disrupting the test environment.

- Advanced Features:Rapid Temperature and Pressure Cycling: The chamber can quickly shift between different temperature and pressure conditions to simulate conditions such as thermal shock, rapid pressure changes, and cyclic humidity exposure.Safety Features: Includes built-in alarms, pressure relief valves, and emergency shutdown systems to protect the machine and users from potential malfunctions.

- Test Standards and Compliance:The HAST chamber is commonly used to comply with industry standards such as:J-STD-020 (Moisture Sensitivity Levels for Components) for semiconductor components.AEC-Q101 (Automotive Electronics Stress Testing).IPC/JEDEC J-STD-033 (Handling, Packing, Shipping, and Use of Moisture/Reflow Sensitive Surface Mount Devices).ISO 16750 (Automotive Environmental Conditions and Testing for Electrical and Electronic Equipment).

Applications:

- Electronics Testing:Semiconductors and PCB Components: One of the most common applications of HAST is testing the reliability of semiconductors, integrated circuits, and PCB (printed circuit board) components. These components are exposed to high temperature, humidity, and pressure in the HAST chamber to accelerate their failure modes and observe their aging behavior.Consumer Electronics: Testing consumer electronics such as smartphones, tablets, and laptops for their long-term reliability in harsh environments.Failure Analysis: HAST is used to detect latent defects in electronic components, providing critical insights into their expected lifespan and failure points.

- Automotive Industry:Electronics in Vehicles: Automotive electronics (e.g., sensors, control units) are tested in HAST chambers to simulate prolonged exposure to high heat and humidity, ensuring that they will withstand harsh driving conditions, including high-pressure environments.Material Testing: Components such as rubber seals, coatings, and plastics used in vehicles are tested for durability under accelerated aging conditions.

- Aerospace and Defense:Aircraft Components: Parts used in aerospace, including sensors, actuators, and electronic systems, are subjected to HAST testing to ensure reliability under high-pressure and extreme environmental conditions.MIL-STDEquipment: Defense-related materials and electronics need to endure a range of environmental stresses, including high humidity, temperature, and pressure. HAST simulates these conditions for accelerated life testing.

- Consumer Goods:Packaging: Packaging materials, especially those that need to protect products in extreme environments, are tested under HAST conditions to ensure they maintain their integrity over time.Batteries: Batteries used in high-demand applications (e.g., electric vehicles, renewable energy storage, and electronics) are tested to determine their performance under accelerated aging, simulating years of use in a short time.

- Material Science and Research:Polymers and Coatings: Testing the effects of temperature, pressure, and humidity on the physical properties of materials such as plastics, rubbers, and coatings, to determine their durability over time.Corrosion Testing: Corrosion of metals under high humidity and temperature conditions can be accelerated in a HAST chamber to predict lifespan and performance in real-world environments.

Advantages of HAST High-Pressure Accelerated Aging Test Chambers:

- Time Efficiency: Accelerates the aging process of materials or components, allowing manufacturers to perform long-term reliability tests in a fraction of the time.

- Realistic Simulation: Provides a highly controlled environment to simulate harsh real-world conditions, making it ideal for testing the durability and performance of materials over extended periods.

- Cost Savings: By speeding up the testing process, manufacturers can identify potential failure modes and weaknesses before mass production, reducing the risk of costly recalls or failures.

- Versatility: Suitable for a wide range of materials, including electronics, automotive parts, packaging, and more.

How It Works:

- Test Setup: The user programs the desired temperature, humidity, and pressure conditions through the control system.

- Sample Placement: Test samples are loaded into the chamber, which is sealed to maintain the high-pressure environment.

- Accelerated Aging: The chamber then simulates accelerated aging by maintaining high temperature, humidity, and pressure for the programmed duration.

- Monitoring: During the test, real-time monitoring ensures that the temperature, humidity, and pressure remain within the set parameters.

- Results Analysis: After the test, the samples are analyzed for failure modes, such as material degradation, corrosion, or performance issues.

Recommended products