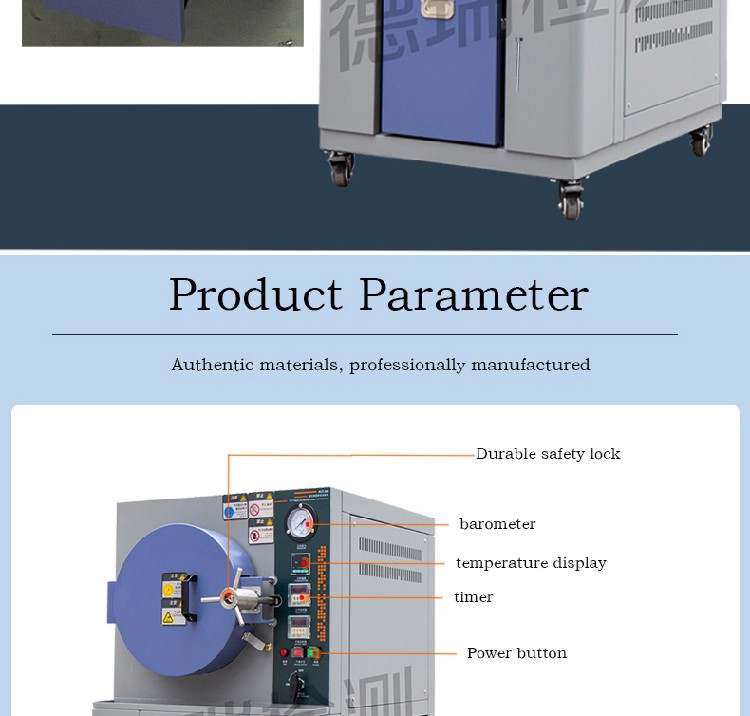

Temperature and humidity controlled HAST high-pressure accelerated aging test chamber

Product description

A Temperature and Humidity Controlled HAST (Highly Accelerated Stress Test) High-Pressure Accelerated Aging Test Chamber combines the principles of HAST testing with controlled temperature, humidity, and high-pressure conditions. This integrated system accelerates the aging process of materials, components, and electronics by simulating extreme environmental conditions, enabling faster evaluation of product reliability over long periods. The combination of high temperature, high humidity, and elevated pressure creates conditions that are more stressful than typical environments, providing manufacturers and researchers a way to identify potential issues with materials and devices early in the development process.

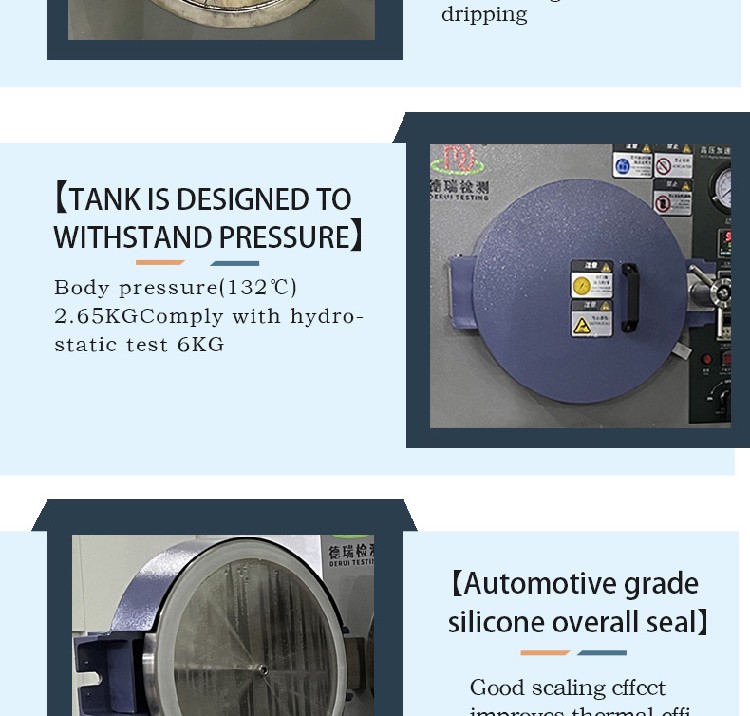

Key Features of a Temperature and Humidity Controlled HAST High-Pressure Accelerated Aging Test Chamber:

- High-Temperature and High-Humidity Control:Temperature Range: Typically from +85°C to +200°C or higher, depending on the specific chamber design. Some systems are designed to reach up to 250°C.Humidity Range: The chamber can generate relative humidity levels of 85% RH to 98% RH, which accelerates the degradation process, especially for sensitive materials and electronic components.Temperature and Humidity Uniformity: Ensures that all test samples within the chamber are exposed to the same environmental conditions, providing consistent and reliable test results.

- High-Pressure Environment:Pressure Range: The chamber is capable of maintaining pressures up to 2 to 3 bars (200-300 kPa), simulating high-pressure environments often encountered at higher altitudes or in sealed enclosures such as aerospace and underwater applications.Pressure Control: The high-pressure system regulates and maintains the set pressure with precision to replicate harsh environmental conditions that affect materials, including corrosion and material degradation under pressure.Pressure Cycling: Some chambers offer the ability to cycle the pressure, creating fluctuations in pressure similar to conditions such as transportation, altitude changes, or the operation of pressure-sensitive devices.

- Accelerated Aging Simulation:Rapid Aging Process: By combining high temperature, high humidity, and high pressure, the test chamber accelerates the aging of materials or components, reducing the time required to simulate years of real-world use. This makes it possible to test a product’s long-term durability and reliability in days or weeks.Simulated Harsh Environments: This type of testing simulates extreme environmental conditions such as those encountered in space, deep-sea exploration, automotive, and environments, where materials or electronics are exposed to extreme conditions for extended periods.

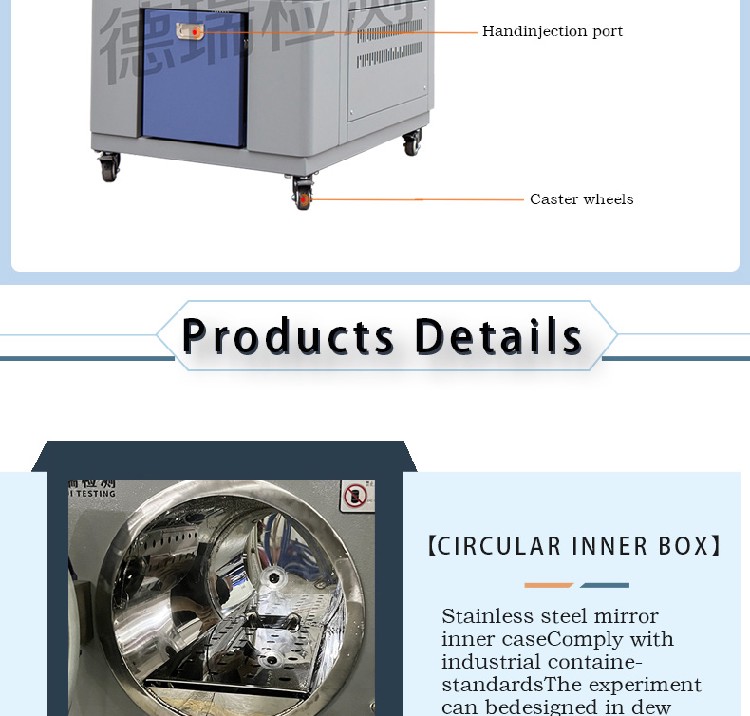

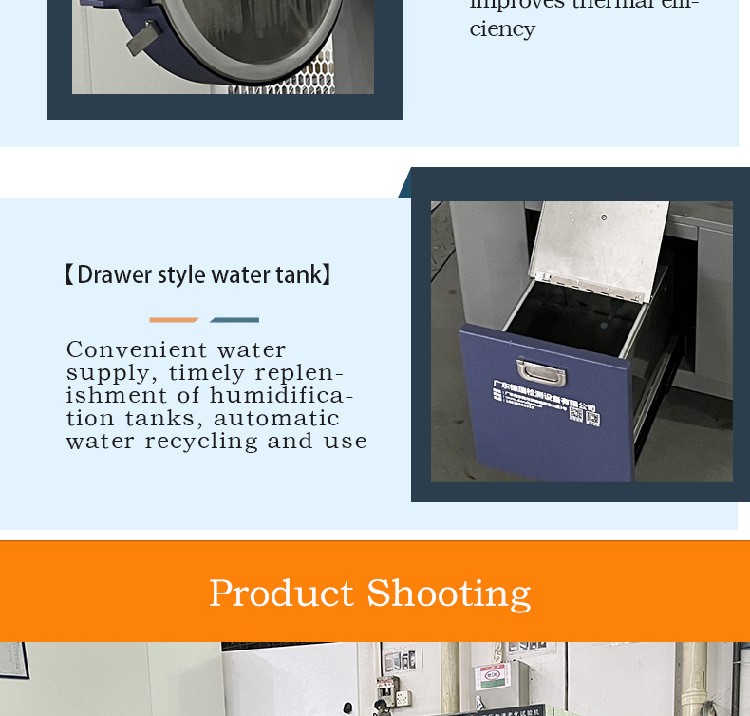

- Advanced Control and Automation:Touchscreen Interface: Modern chambers typically come with a user-friendly touchscreen interface that allows easy configuration of test parameters, including temperature, humidity, pressure, and test duration.Programmable Test Profiles: Users can program the chamber for specific testing profiles, with control over temperature ramps, humidity hold times, and pressure cycles to replicate the exact environmental conditions required for a given test.Data Logging and Monitoring: The chamber is equipped with sensors that log temperature, humidity, and pressure in real time, allowing for continuous monitoring. Detailed logs can be exported in various formats (e.g., CSV, Excel) for further analysis.

- Sample Load and Testing Capacity:Sample Racks or Trays: Test samples are placed in racks or trays within the chamber, ensuring uniform exposure to the test environment.Sample Size Flexibility: The chamber may accommodate a wide variety of sample sizes, from small electronics components to larger devices, making it versatile for a wide range of industries.High-Volume Testing: Multiple test samples can be tested simultaneously, enhancing the throughput and efficiency of the testing process.

- Safety and Operational Features:Pressure Relief Valves: To ensure safe operation, the chamber is equipped with safety mechanisms such as pressure relief valves to prevent over-pressurization.Temperature and Pressure Alarms: If the temperature or pressure exceeds safe limits, the system triggers alarms to alert operators and prevent damage to both the machine and the samples.Automatic Shutdown: In the event of malfunction or emergencies, the system can automatically shut down to prevent any further damage to the equipment or samples.

- Reliability Testing for Electronics and Materials:Electronic Components: Widely used in the electronics industry for testing semiconductors, integrated circuits (ICs), capacitors, and other electronic components to evaluate their long-term reliability under stressful conditions.Material Testing: This chamber can be used to test materials such as polymers, coatings, and composite materials for use in harsh environments, simulating the effects of prolonged exposure to high temperatures, humidity, and pressure., Aerospace, and Automotive: Particularly beneficial for testing , aerospace, and automotive components that must operate under extreme conditions, such as avionics, sensors, or parts exposed to high altitudes, deep-sea pressures, or varying atmospheric conditions.

Applications of Temperature and Humidity Controlled HAST High-Pressure Accelerated Aging Test Chamber:

- Electronics Industry:Semiconductor Reliability: Testing of semiconductors (such as ICs, transistors, and capacitors) under harsh environmental conditions to ensure they perform reliably in real-world conditions. It’s particularly useful for high-performance, mission-critical components.Printed Circuit Boards (PCBs): Accelerated aging of PCB assemblies that are used in electronics such as smartphones, tablets, and automotive control units.Failure Analysis: Identifying potential failure mechanisms in electronic components that may not be evident under normal use conditions.

- Automotive Industry:Electronic Components: Testing of automotive electronics (e.g., ECUs, sensors, connectors) that must perform under varying temperature, humidity, and pressure conditions experienced during operation in different climates.Vehicle Parts: Rubber seals, plastic parts, coatings, and other components subjected to prolonged exposure to high pressure, humidity, and temperature in harsh environments, such as under the hood of a vehicle or during long-term storage.

- Aerospace and Defense:Avionics Testing: Aerospace electronics and components such as navigation systems, sensors, and communication systems are tested for durability in extreme atmospheric conditions.High-Pressure Environments: Testing parts designed for high-pressure, high-altitude, or vacuum environments, including components for space exploration and applications.Reliability Under Extreme Conditions: and aerospace equipment subjected to prolonged exposure to high pressure, extreme humidity, and elevated temperatures to simulate long-term use and verify operational reliability.

- Consumer Electronics:Smartphones, Tablets, and Wearables: Testing consumer electronics devices for their ability to withstand harsh environmental conditions during prolonged use, including testing under high heat and humidity.Battery Testing: Batteries used in consumer devices and electric vehicles are subjected to stress tests that simulate prolonged exposure to environmental stress factors, accelerating wear and tear in a controlled manner.

- Material Science and Manufacturing:Material Durability: Testing the durability of materials used in coatings, plastics, composites, and metals that must perform reliably in extreme weather conditions or hazardous environments.Corrosion Testing: Accelerated corrosion testing of materials (such as metals and alloys) used in marine, automotive, and industrial applications.

- Pharmaceutical and Packaging Industries: Packaging: Testing of packaging materials for pharmaceuticals, ensuring that they maintain their integrity and performance when exposed to extreme conditions, including high humidity and temperature cycling.Packaging Materials: Evaluation of materials used for protective packaging of sensitive products, such as electronics or medical devices.

Benefits of Using a Temperature and Humidity Controlled HAST High-Pressure Accelerated Aging Test Chamber:

- Speed: Accelerates the aging process, allowing manufacturers to identify potential failures much faster than traditional testing methods.

- Simulated Real-World Conditions: Provides a reliable simulation of extreme environments to ensure that products can withstand real-world conditions in a compressed time frame.

- Cost-Effective: By identifying issues early in the development cycle, it helps manufacturers avoid costly product recalls and ensure long-term product reliability.

- Comprehensive Testing: Combines multiple environmental stressors (temperature, humidity, pressure) in a single test, making it ideal for products exposed to varying or unpredictable environments.

If you need more details on specific chamber models or manufacturers, or if you are interested in particular features for a certain application, feel free to let me know!

Recommended products