Ceramic Fiber Materials: Powering Efficiency in Extreme Heat Environments

Product description

Product Definition

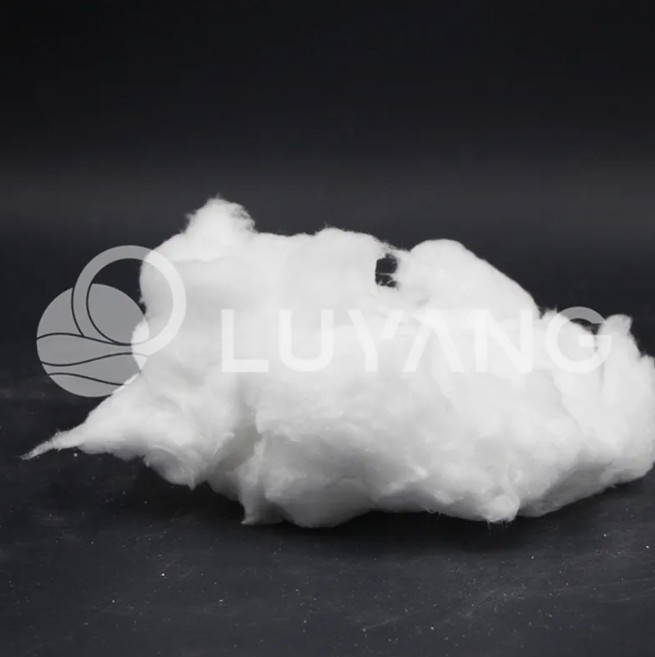

Ceramic fiber materials are engineered and inorganic refractory solutions designed for unparalleled thermal management in the world's most demanding high-temperature processes. Crafted predominantly from alumina-silica compounds, these materials are transformed into a network of fine and interlocking fibers through specialized melting and spinning techniques. This creates an ultra-lightweight and low-density matrix with exceptional insulating characteristics. Offered in versatile formats, including resilient blankets, rigid boards, modular components, bulk fibers, papers, and textiles, ceramic fiber products deliver critical thermal protection across diverse industries. Their fundamental capability is reliable and long-term performance in continuous service environments ranging from 1260°C (2300°F) to 1600°C (2912°F), achievable through specific formulations (Standard, High-Purity, Zirconia-Enhanced).

This unique fibrous architecture forms an effective thermal barrier, significantly resisting heat transfer by conduction and convection. The adaptability of many forms allows for precise installation on intricate equipment profiles and within constrained spaces, ensuring comprehensive insulation coverage.

Operational Benefits

1. Revolutionary Energy Savings: Exceptionally low thermal conductivity slashes heat loss, directly reducing energy consumption by 20-40%+ compared to traditional refractories, lowering operating costs and environmental footprint.

2. Accelerated Process Cycles: Minimal thermal mass enables rapid heating and cooling of furnaces, kilns, and reactors, boosting throughput, productivity, and operational flexibility.

3. Peak High-Temperature Performance: Maintain structural integrity and insulating effectiveness under sustained ultra-high heat, protecting equipment and ensuring process stability where conventional materials fail.

4. Unrivaled Thermal Shock Resistance: Withstand severe and rapid temperature swings without cracking or spalling, guaranteeing reliability in cyclical operations and frequent startups or shutdowns.

5. Enhanced Personnel Safety: Drastically reduce external surface temperatures on hot equipment, mitigating burn hazards and creating safer working environments.

6. Lightweight Engineering Advantage: Significantly reduce structural load (vs. brick/monolithics), simplifying support design, easing installation, and lowering foundation costs.

7. Superior Chemical Durability: Resist degradation from most acids, solvents, oils, and oxidizing or reducing atmospheres (exclusions: strong alkalis, hydrofluoric acid), extending service life in harsh conditions.

8. Installation Versatility & Speed: Flexible blankets and pre-formed modules conform effortlessly to complex shapes, drastically cutting installation time and labor costs while eliminating thermal bridging.

9. Optimized Equipment Protection: Create a stable thermal barrier, minimizing thermal stress on critical equipment components and extending asset lifespan.

10. Robust Solutions Spectrum: Comprehensive range of forms and grades tailored for specific needs: resilient blankets for curved surfaces, durable boards for flat walls or floors, modules for rapid lining, textiles for gaskets or seals, and bulk for filling.

11. Acoustic Insulation Bonus: The fibrous structure inherently dampens noise from high-temperature machinery, contributing to a quieter plant environment.

12. Lifecycle Cost Reduction: Combine energy savings, reduced maintenance, extended equipment life, and lower installation costs for a superior total cost of ownership.

Why Ceramic Fiber?

For industries operating at the edge of thermal capability, including metal processing, petrochemicals, power generation, ceramics, glass, and aerospace, ceramic fiber materials are not just insulation-they are critical performance enablers. They transform high-heat operations by:

1. Maximizing Energy Efficiency: Directly cutting fuel or electricity costs.

2. Boosting Productivity: Enabling faster process cycles.

3. Ensuring Reliability: Withstanding extreme thermal and mechanical stress.

4. Protecting Investments: Safeguarding equipment integrity.

5. Enhancing Safety: Creating cooler external surfaces.

Embrace the advanced thermal management capabilities of ceramic fiber materials to optimize performance, reduce costs, and achieve new levels of operational excellence in your high-temperature processes.

Why Choose Us?

Luyang Energy-Saving Materials Co., Ltd. is a leading manufacturer dedicated to developing, producing, and supplying high-performance thermal insulation and energy-saving solutions for diverse construction and industrial applications worldwide. Leveraging advanced material science and rigorous quality control, the company offers a comprehensive portfolio of innovative products designed to significantly reduce energy consumption, lower carbon emissions, enhance building efficiency, and provide sustainable economic benefits to its global clientele.

Recommended products