Tree Debarkers: Efficient Bark Removal for Forestry Operations

Product description

Product Introduction

Tree debarkers are robust and purpose-built machines designed to efficiently and cleanly remove bark from logs immediately after felling. They serve as a crucial piece of equipment in modern timber processing, handling logs ranging from small-diameter thinnings to large industrial timber. Debarkers operate using various mechanisms, the most common being rotating cutter heads equipped with hardened steel knives or flails that shear or chip away the bark layer as the log is rotated and fed through the machine. Key configurations include:

1. Mobile Debarkers: Mounted on trailers or truck beds, these units are highly versatile and can be transported directly to the harvest site (in-forest) or landing area. This enables processing close to the source, significantly reducing the need to transport bulky and bark-covered logs.

2. Stationary Debarkers: Larger and fixed installations typically found at sawmills, pulp mills, or central processing yards. Designed for high-volume and continuous operation, often integrated into larger processing lines.

3. Feed Systems: Logs are typically fed through the debarking chamber using hydraulic feed rollers or chains, ensuring consistent rotation and forward movement for uniform bark removal.

4. Debarking Mechanisms: Common types include:

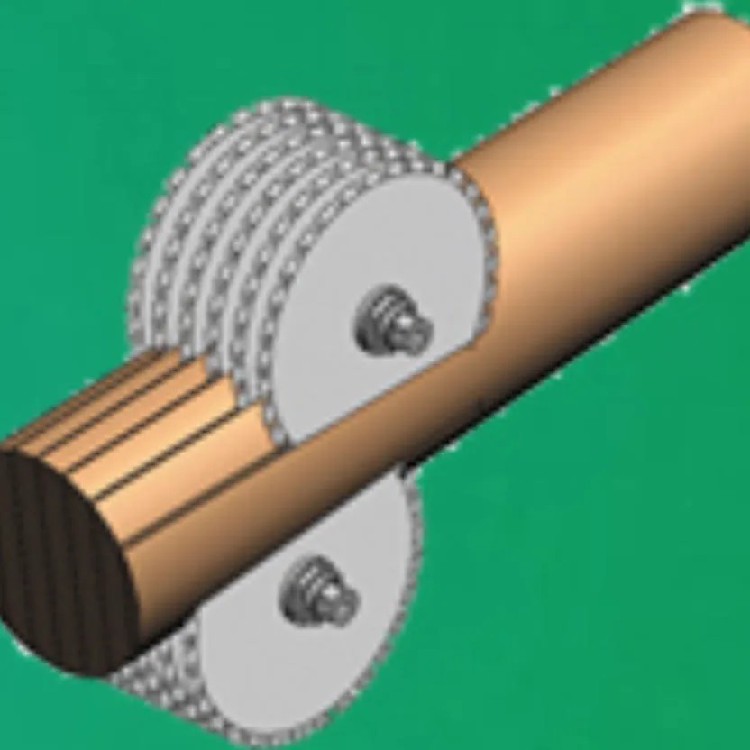

- Ring Debarkers (Cutter Head): A rotating ring with knives presses against the rotating log, shearing off the bark.

- Flail Debarkers: Rotating drums equipped with heavy swinging flails or hammers that beat the bark off the log.

- Rosser Head Debarkers: Utilize rotating heads with protruding tools that chip away bark as the log passes through.

Product Advantages

1. Significantly Increased Efficiency & Productivity: Debarkers dramatically speed up the bark removal process compared to manual methods or older mechanical systems. They can process a high volume of logs per hour, streamlining the entire timber supply chain.

2. Reduced Transportation Costs: By removing bark (which can constitute a significant portion of a log's weight and volume, especially for smaller logs) directly at the forest site or landing, mobile debarkers drastically reduce the tonnage and volume of material needing transport to mills. This translates to substantial savings in fuel and hauling expenses.

3. Improved Log Quality & Value: Precise debarking minimizes damage to the underlying wood surface. Clean and debarked logs are essential for high-quality lumber production (reducing planer wear and tear and improving surface finish), veneer peeling, and ensuring optimal chip quality for pulp mills. Clean logs also command higher market prices.

4. Lower Labor Costs & Enhanced Safety: Automating the strenuous and potentially hazardous task of manual debarking significantly reduces labor requirements and exposure to injury risks associated with hand tools or chainsaws.

5. Reduced Wood Waste: Modern debarkers are designed to remove bark efficiently while minimizing the loss of valuable wood fiber underneath, maximizing usable timber yield from each log.

6. Versatility: Many debarkers are designed to handle a wide range of log diameters, species (both hardwoods and softwoods), and lengths, adapting to diverse forestry operations.

7. Site Cleanliness & Environmental Benefits: Processing logs at the landing or in the forest with a mobile debarker concentrates bark waste in a controlled area, making collection for biomass fuel or other uses easier and reducing debris scattered across the harvest site. Cleaner logs also mean less dirt and bark contamination entering the mill.

8. Optimized Downstream Processing: Delivering clean and debarked logs to sawmills, pulp mills, or chipping operations improves the efficiency and quality of all subsequent processing stages, leading to higher overall output and product quality.

Tree debarkers are an indispensable investment for forestry operations focused on maximizing efficiency, reducing costs, improving log quality, and optimizing the entire timber processing workflow from forest to mill.

Who We Are?

Yucheng Runming Machinery Co., Ltd. is a dedicated manufacturer and supplier of high-quality industrial machinery and equipment, strategically located in Yucheng, China. Leveraging years of expertise and a commitment to technological advancement, we specialize in the design, production, and distribution of robust and reliable machinery solutions tailored to meet diverse industry needs. Our comprehensive product range emphasizes precision engineering, operational efficiency, and durability, supported by stringent quality control processes adhering to international standards. Focused on customer satisfaction and innovation, Yucheng Runming Machinery partners with clients globally, providing expert technical support and responsive service to build long-term, trusted relationships and deliver optimal performance solutions for a competitive market.

Recommended products