Tree Debarkers: Unlocking Efficiency and Value in Timber Processing

Product description

Product Overview

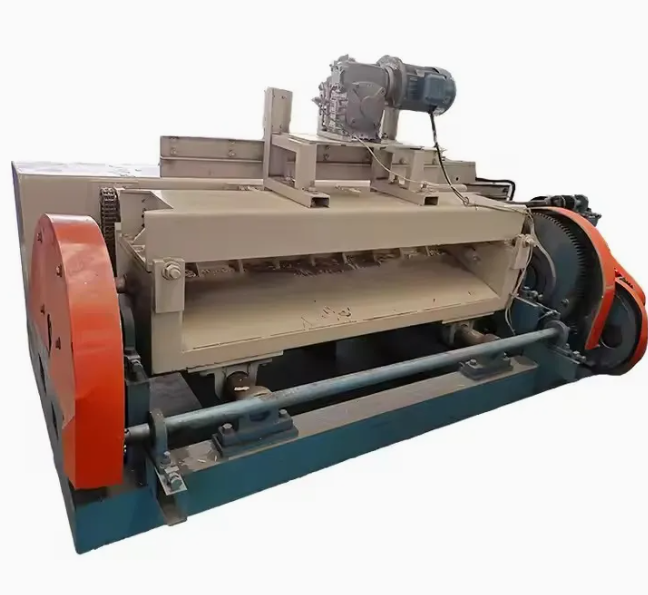

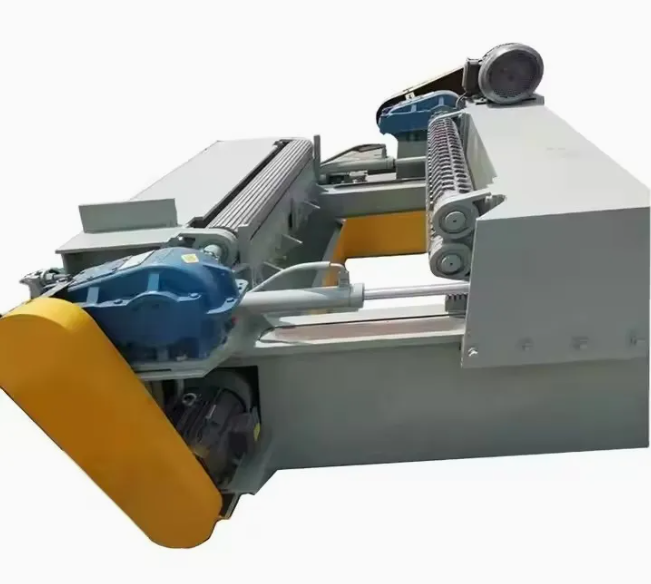

Tree Debarkers are specialized industrial machines engineered to rapidly and effectively remove bark from harvested logs. Serving as a critical first step in modern timber processing, they transform raw and bark-covered logs into clean feedstock ready for sawmills, veneer mills, pulp mills, or biomass facilities. These robust machines utilize mechanical force, typically rotating cutter heads, flails, or abrasive surfaces to shear, chip, or beat the bark away as logs are systematically fed through the processing chamber. Debarkers are designed to handle a vast spectrum of log sizes and species, adapting to diverse forestry and mill environments.

Key Configurations & Operation

1. Mobility: Available in mobile configurations (mounted on trailers or truck chassis) for in-forest or landing operation, and stationary configurations for high-volume and fixed-site processing within mills or centralized yards.

2. Feed Mechanism: Hydraulic rollers or chain systems grip and rotate the log while steadily advancing it through the debarking chamber, ensuring consistent contact with the debarking elements.

3. Debarking Technology: Common effective methods include:

- Rotary Cutter Heads: A ring or drum equipped with hardened steel knives presses against the rotating log, shearing off the bark layer cleanly.

- Flail Systems: Rotating drums with heavy, freely swinging steel hammers or flails impact the log surface, effectively knocking and chipping the bark loose.

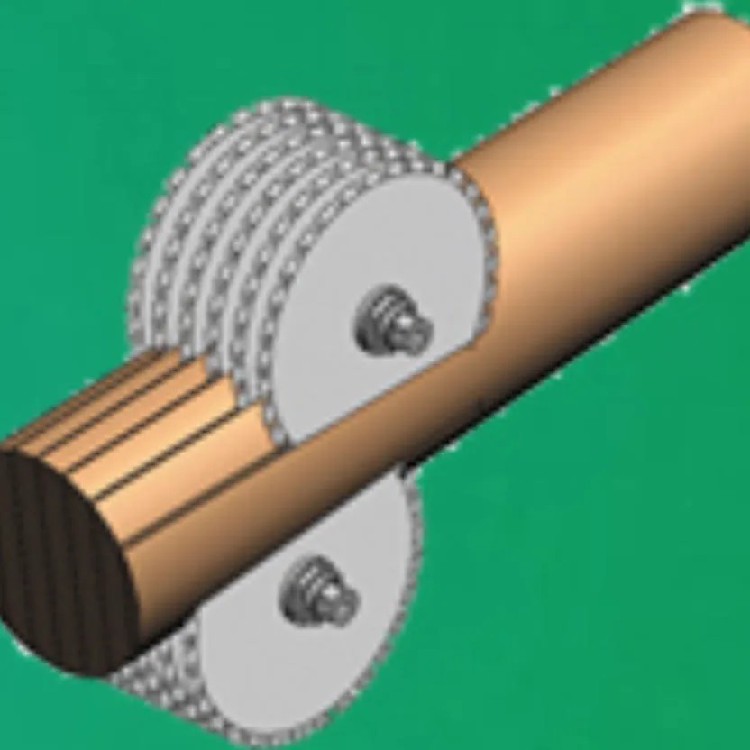

- Abrasive Drum: Logs are tumbled against a rotating drum lined with abrasive material like carbide stars which scrubs the bark off.

Compelling Advantages

1. Dramatic Cost Savings on Transport: Bark constitutes a significant portion of a log's volume and weight (often 15-30% or more). Mobile debarkers processing at the stump or landing eliminate hauling this waste, drastically reducing truckloads, fuel consumption, and overall transportation expenses.

2. Enhanced Log Value & Product Quality: Clean and undamaged wood surfaces are essential. Debarkers provide:

- Superior Lumber & Veneer: Minimize surface defects, reduce planer wear, and improve finish quality.

- Optimum Pulp Chips: Prevent bark contamination which lowers pulp yield and quality.

- Increased Market Value: Clean logs command higher prices consistently.

3. Unmatched Processing Speed & Efficiency: Automate a labor-intensive task, processing far more logs per hour than manual methods or older equipment, accelerating throughput from forest to mill.

4. Significant Labor Reduction & Improved Safety: Eliminate the need for dangerous and physically demanding manual debarking, lowering labor costs and minimizing risks associated with hand tools, chainsaws, and repetitive strain.

5. Maximized Fiber Utilization: Precision-engineered debarking minimizes the loss of valuable wood fiber beneath the bark, maximizing usable yield per log.

6. Operational Flexibility: Capable of processing a wide range of log diameters, lengths, and species (both softwoods and hardwoods), making them suitable for diverse operations from thinning to large-scale harvests.

7. Improved Site Management & Environmental Benefits:

- Concentrated Waste: Bark waste is collected at a single point (landing or mill), facilitating efficient removal or utilization as biomass fuel, mulch, or landscaping material.

- Reduced Mill Contamination: Clean logs minimize dirt, stones, and bark debris entering the mill, protecting downstream equipment and improving mill cleanliness.

- Forest Floor Tidiness: In-forest processing reduces bark scatter across harvest sites.

8. Optimized Downstream Operations: Delivering consistently clean logs significantly boosts the efficiency, productivity, and output quality of all subsequent processing stages (sawing, chipping, peeling, pulping).

Investing in Productivity

Tree Debarkers are not just bark removal machines; they are strategic investments that streamline the entire timber value chain. By significantly reducing transport costs, boosting log value, enhancing safety, improving operational efficiency, and supporting better resource utilization, modern debarkers deliver a powerful return on investment for forward-thinking forestry and milling operations. They are fundamental technology for maximizing profitability and sustainability in today's timber industry.

About Us

Yucheng Runming Machinery Co., Ltd. is a dedicated manufacturer and supplier of high-quality industrial machinery and equipment, strategically located in Yucheng, China. Leveraging years of expertise and a commitment to technological advancement, we specialize in the design, production, and distribution of robust and reliable machinery solutions tailored to meet diverse industry needs. Our comprehensive product range emphasizes precision engineering, operational efficiency, and durability, supported by stringent quality control processes adhering to international standards. Focused on customer satisfaction and innovation, Yucheng Runming Machinery partners with clients globally, providing expert technical support and responsive service to build long-term, trusted relationships and deliver optimal performance solutions for a competitive market.

Recommended products