How to choose safe and comfortable Safety Shoes

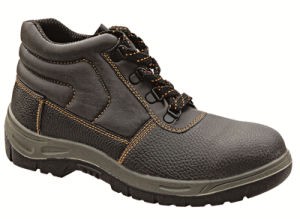

Product description

Imagine dropping a heavy toolbox on your foot – without protection, that could mean broken bones and months off work. Safety shoes are the unsung heroes of hazardous workplaces, designed specifically to shield your feet from such everyday dangers. More than just durable footwear, they’re engineered lifesavers.

Why Safety Shoes Aren’t Just "Heavy Boots"

Unlike regular shoes, safety shoes integrate critical protective features:

Toe Protection: A reinforced toe cap (usually steel, aluminum, or composite) guards against crushing injuries from falling objects. This is the hallmark feature (often called "steel toes" colloquially).

Puncture Resistance: A tough midsole stops sharp objects like nails or glass from penetrating the sole.

Slip Resistance: Specially designed treads provide grip on oily, wet, or slippery surfaces, preventing falls.

Electrical Hazard Protection: Insulating materials reduce the risk of electric shock in environments with live circuits.

Impact & Compression: Protection extends beyond the toes, shielding the entire foot from rolling objects or compression hazards.

Metatarsal Guard: Additional protection for the vulnerable upper foot bones (an add-on or built-in feature).

Comfort & Support: Modern designs prioritize ergonomics, arch support, cushioning, and breathability for all-day wear.

Who Needs Safety Shoes? It’s More Than Just Construction!

While construction workers are the classic example, safety shoes are vital across numerous industries:

Manufacturing & Warehousing: Protection from machinery, heavy loads, and dropped items.

Logistics & Transportation: Handling freight, slip resistance on docks.

Electrical & Utilities: Protection against electrical hazards and live wires.

Oil, Gas & Chemicals: Slip resistance, protection from chemicals, and potential explosions (safety toe required in hazardous areas).

Healthcare & Laboratories: Protection from dropped sharps, biohazards, and chemicals.

Agriculture & Landscaping: Protection from tools, equipment, and puncture hazards.

Automotive: Protection from heavy parts, oils, and workshop hazards.

Choosing the Right Safety Shoe: Fit & Function First!

Don’t just grab any pair! Consider:

Your Specific Hazards: What risks dominate your job? (Impact? Punctures? Electricity? Slippery floors? Chemicals?)

Required Safety Standards: Look for certification labels like ASTM (USA/Canada), EN ISO (Europe), or AS/NZS (Australia/NZ). Common standards include:

ASTM F2413: Covers impact (I), compression (C), puncture resistance (PR), EH, etc.

EN ISO 20345: Similar standards (e.g., S1, S3 ratings denote different safety features).

Perfect Fit: Ill-fitting shoes cause discomfort and blisters, discouraging wear. Get professionally measured! Ensure ample toe room with the safety cap and good heel support.

Comfort Features: Look for cushioning, breathable linings, moisture-wicking properties, and supportive insoles. You’ll wear them for hours!

Durability & Materials: Leather offers durability; synthetic materials may be lighter or more chemical-resistant. Consider the sole material's grip and oil resistance.

Caring for Your Safety Shoes: Make Them Last

Clean Regularly: Wipe off dirt, oils, and chemicals immediately to prevent material degradation. Follow manufacturer cleaning instructions.

Dry Thoroughly: Never dry near direct high heat (like a furnace). Stuff with newspaper in a well-ventilated area.

Inspect Often: Check for cracks in the sole, excessive wear, damage to the toe cap, or worn-down treads. Replace damaged shoes immediately – compromised protection is no protection.

Rotate if Possible: Having a second pair allows each to air out, extending lifespan.

Investing in Safety is Investing in Yourself

Safety shoes are not an optional extra; they are fundamental Personal Protective Equipment (PPE). They prevent debilitating injuries, reduce lost work time, and provide peace of mind. Modern safety footwear combines robust protection with impressive comfort – there’s no need to sacrifice safety for all-day wearability.

Before stepping onto your worksite, ask yourself: Are your feet truly protected? Choosing and wearing the right safety shoes is one of the smartest decisions you can make for your health, your livelihood, and your ability to walk comfortably at the end of every shift.

Q&A Section (For User & Search Queries)

Q: Are safety shoes really comfortable?

A: Absolutely! Modern designs prioritize ergonomics with features like memory foam, athletic-style midsoles, and lightweight materials, making them far more comfortable than older, clunkier models.

Q: How often should I replace my safety shoes?

A: Typically every 6-12 months with regular use, but inspect them monthly. Replace immediately if you see cracks, holes, exposed toe caps, or worn-out treads. Comfort degradation is also a sign.

Q: Can I wear regular insoles in my safety shoes?

A: Usually yes, but ensure they don’t compromise the fit or pressure points, especially around the toe cap. Remove the factory insole first. Some safety shoes have built-in, certified anti-fatigue insoles.

Q: What does "EH" mean on my safety shoes?

A: "EH" stands for Electrical Hazard. It means the shoe provides secondary protection against accidental contact with live electrical circuits (under specific dry conditions), reducing the risk of shock. It does not make them electrically insulated for working directly on live parts.

Q: Are composite toe caps as good as steel?

A: Composite toes (made from materials like Kevlar, plastic, fiberglass) meet the same impact/compression safety standards (ASTM/EN) as steel. They are lighter, don’t conduct temperature (better in hot/cold extremes), and are non-metallic (good for metal detectors or electrical work). Steel is generally thinner, allowing for a sleeker profile.

Recommended products