The Engine of Modern Construction: Your Guide to Advanced Brick Making Machinery

Product description

For two decades, the pulse of efficient and scalable construction has been powered by sophisticated brick making machinery. This isn't just about forming clay or concrete; it's about transforming raw materials into the fundamental building blocks of our world with unprecedented speed, precision, and reliability. Today's leading systems represent the pinnacle of engineering designed to meet the rigorous demands of high-volume production while offering remarkable versatility and operational efficiency.

Unmatched Precision and Robust Engineering

At the core of high-performance brick making machinery lies exceptional engineering. Heavy-duty frames, constructed from reinforced steel, provide the necessary stability to withstand the immense pressures involved in compaction. Advanced hydraulic systems deliver consistent and powerful force often exceeding 1000 tons, ensuring that every brick, block, or paver achieves optimal density and dimensional accuracy down to the millimeter. This precise control over the forming process guarantees uniform products batch after batch, eliminating waste and ensuring seamless integration on the construction site. Sophisticated vibration technology often with adjustable frequency and amplitude works in concert with the hydraulics to thoroughly compact the raw material mix, expelling air pockets and creating incredibly strong and durable finished products.

Driving Productivity and Profitability

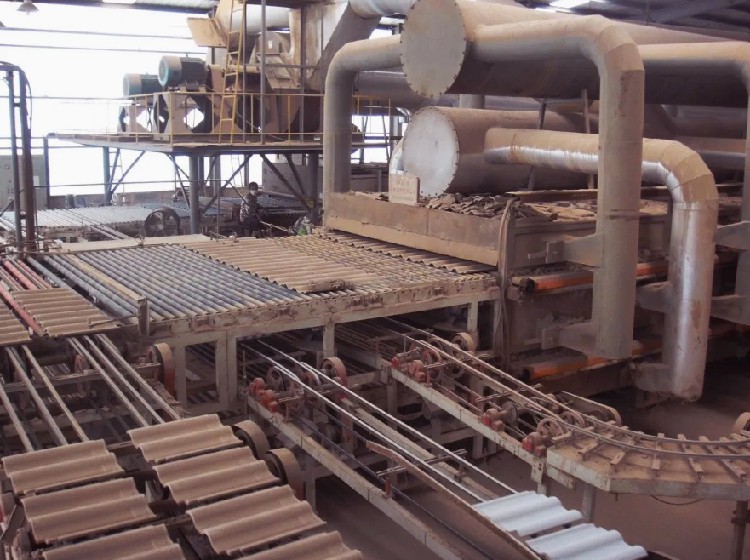

The true power of modern brick making equipment is measured in output and efficiency. Fully automated systems can produce thousands of high-quality bricks or blocks per hour, dramatically outpacing manual methods and significantly reducing labor costs. Integrated material handling systems, including automated feeders, mixers, and conveyors, streamline the entire workflow, minimizing manual intervention and maximizing uptime. Quick-change mold systems are a critical feature, allowing operators to switch between producing different brick types, sizes from standard bricks to large hollow blocks or intricate pavers, and surface textures within minutes. This flexibility enables producers to respond swiftly to diverse market demands without costly downtime. Furthermore, advanced control panels with user-friendly interfaces, often featuring PLC (Programmable Logic Controller) systems, allow for precise parameter setting, process monitoring, and troubleshooting, ensuring consistent quality and minimizing operational errors.

Versatility in Materials and Applications

Modern brick machinery is remarkably adaptable. It efficiently processes a wide spectrum of raw materials:

1. Concrete: Produce a vast array of standard concrete blocks, hollow blocks, paving stones, and landscaping products.

2. Clay: Form robust fired bricks for structural and aesthetic applications (requires integration with drying and kiln systems).

3. Fly Ash: Utilize this industrial by-product to create eco-friendly bricks and blocks.

4. Soil or Cement Mixtures: Ideal for stabilized earth blocks (CSEB) in specific regions and applications.

5. Other Additives: Incorporate pigments, reinforcing fibers, or other materials to enhance product characteristics.

This material versatility translates directly into diverse applications. The machinery produces essential components for:

1. Residential Construction: Load-bearing blocks, partition walls, and facing bricks.

2. Commercial & Industrial Projects: Large-format blocks, paving for heavy traffic areas.

3. Infrastructure Development: Kerbstones, drainage channels, and retaining wall blocks.

4. Landscaping & Hardscaping: Decorative pavers, garden wall blocks, and edging stones.

5. Specialized Products: Interlocking blocks, acoustic blocks, and insulated blocks.

Sustainability and Long-Term Value

Investing in advanced brick making machinery is an investment in sustainable production and long-term operational resilience. Efficient designs minimize energy consumption per unit produced. The ability to utilize waste materials like fly ash contributes to a circular economy. Reduced waste from precise forming and consistent quality lowers environmental impact and material costs. Crucially, these machines are built for endurance. High-grade components, accessible service points, and robust construction ensure decades of reliable service when properly maintained, delivering an exceptional return on investment through continuous and high-volume production.

The Foundation of Your Success

Whether you're establishing a new production facility or upgrading existing capacity, selecting the right brick making machinery is pivotal. Look for systems that deliver the critical combination of industrial-strength durability, high automation for peak productivity, exceptional versatility across materials and products, and user-centric operation. This is the machinery that empowers manufacturers to meet the scale and quality requirements of contemporary construction projects, laying a solid foundation for business growth and leadership in the competitive building materials market. Explore the capabilities of next-generation brick production technology and unlock new levels of efficiency and product excellence.

About Us

Guangxi Hongfa Heavy Machinery Co., Ltd., strategically based in Guangxi, China, is a leading manufacturer specializing in the design, engineering, and production of high-performance heavy machinery for demanding global industries. We leverage advanced manufacturing technology and rigorous quality control to deliver robust and reliable solutions, including crushers, mills, screening equipment, bulk material handling systems, and components tailored for mining, construction, aggregates, cement, and port logistics. Committed to innovation, durability, and customer success, Hongfa provides comprehensive support from consultation and custom engineering to installation, maintenance, and after-sales service, empowering clients worldwide to enhance productivity and operational efficiency. Trust Hongfa for powerful machinery built to endure.

Recommended products