CNC Bending Machines: Precision Metal Shaping for Modern Manufacturing

Product description

For two decades, we've witnessed the evolution of metal fabrication. At its core, bending sheet metal and plate accurately and efficiently remains fundamental. CNC Bending Machines, often called CNC Press Brakes, represent the pinnacle of this capability. These sophisticated machines transform flat metal into complex and three-dimensional components with remarkable consistency, empowering industries worldwide.

Engineered for Unmatched Precision & Control

Modern CNC Bending Machines are marvels of engineering, integrating robust mechanical design with advanced computer numerical control. The heart of the system is the CNC controller, acting as the operator's intelligent interface. Users input bending parameters - angle, bend length, sequence via intuitive software, often featuring graphical simulations to prevent errors. The controller then orchestrates the machine's movements with microscopic precision.

Critical components working in concert include:

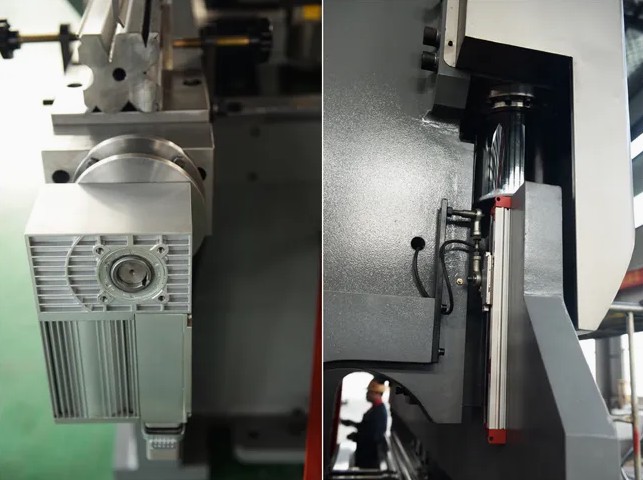

1. The Ram: Driven by powerful hydraulic or electric servo systems, the ram delivers the precise force needed for bending. Electric servo models offer exceptional speed and energy efficiency, while robust hydraulic systems excel with demanding and high-tonnage applications.

2. The Bed & Frame: A massively rigid frame often constructed from high-tensile steel provides the essential stability to withstand immense bending forces without deflection, guaranteeing consistent accuracy part after part.

3. Tooling (Punch & Die): The interchangeable upper punch and lower die determine the bend's shape and angle. Precision-ground tooling is crucial for achieving clean and sharp bends without marring the material surface.

4. Programmable Backgauges: Multi-axis and CNC-controlled backgauges position the metal sheet with extreme accuracy prior to each bend. This automation eliminates manual measuring, reducing setup times and human error drastically.

Tangible Advantages Driving Productivity

Investing in a CNC Bending Machine translates into significant competitive advantages:

1. Exceptional Accuracy & Repeatability: Achieve tolerances within fractions of a degree batch after batch. This consistency is vital for parts requiring strict interchangeability or complex assemblies.

2. Dramatically Reduced Setup Times: Storing programs for recurring jobs allows instant recall. Changing tooling is streamlined often aided by quick-clamp systems, minimizing machine downtime between jobs.

3. Enhanced Efficiency & Throughput: Automated sequences, rapid ram speeds (especially in electric models), and reduced manual handling significantly increase parts production per shift.

4. Lower Operating Costs: Minimized scrap due to precision, reduced labor requirements per part, and optimized material usage contribute directly to a healthier bottom line. Electric servo drives further reduce energy consumption.

5. Complex Part Capability: Easily program intricate bending sequences with multiple bends at different angles on a single part - a task extremely challenging or impossible manually.

6. Improved Operator Safety: CNC operation keeps hands away from the bending point. Integrated safety features like light curtains or laser guards enhance the working environment significantly compared to manual brakes.

Versatile Applications Across Industries

The precision and flexibility of CNC Bending Machines make them indispensable in countless sectors:

1. Metal Enclosures & Cabinets: Produce precise housings for electronics, control panels, server racks, and industrial machinery.

2. Architectural & Building Components: Fabricate structural elements, cladding panels, fascia, gutters, and custom metalwork for construction.

3. Automotive & Transportation: Manufacture brackets, chassis components, exhaust parts, seat frames, and truck body panels.

4. Aerospace & Defense: Create high-precision structural brackets, housings, and ducting where strict tolerances are non-negotiable.

5. HVAC & Ductwork: Form complex ducting systems, vents, and fittings efficiently.

6. Furniture & Fixtures: Craft robust retail displays, shelving units, point-of-purchase stands, and architectural metal furniture.

7. General Fabrication: Serve as the backbone of job shops handling diverse custom metal parts for various clients.

The Foundation of Advanced Fabrication

More than just a machine, a CNC Bending Machine is a strategic asset. It elevates a workshop's capabilities, enabling the production of high-quality and complex parts with speed and reliability that manual processes simply cannot match. By automating precision and significantly boosting throughput, it addresses the core challenges of modern manufacturing: cost-effectiveness, quality control, and the ability to meet demanding production schedules. Whether you're a high-volume producer or a specialized job shop, integrating this technology is a definitive step towards greater efficiency, expanded capabilities, and enhanced competitiveness in the global metalworking landscape. Explore the potential of CNC bending to transform your sheet metal operations.

About Us

Ma'anshan Guoao Heavy Industry Machinery Manufacturing Co., Ltd. stands as a leading force in the design, engineering, and production of robust and high-performance heavy industrial machinery and equipment, dedicated to empowering critical sectors such as mining, construction, metallurgy, and material handling. Leveraging cutting-edge technology, stringent quality control processes, and deep engineering expertise, we deliver precision-engineered solutions including crushers, mills, material processing systems, and bespoke components, renowned for exceptional durability, operational efficiency, and adherence to international standards. Committed to customer success, we offer comprehensive support from initial consultation and custom manufacturing to installation and after-sales service, ensuring reliable performance and maximizing productivity for our global clientele through innovation, ISO-certified manufacturing excellence, and a steadfast focus on exceeding expectations in every project undertaken.

Recommended products