Unlocking the Future of Food Packaging: Revolutionizing Efficiency with Food Packaging Machines

Product description

Food packaging plays a pivotal role in the modern food industry, ensuring that products remain fresh, safe, and appealing to consumers. To meet the growing demand for efficiency, sustainability, and quality, food packaging machines have become indispensable in streamlining operations. These machines are designed to cater to the diverse needs of the food sector from small-scale artisanal producers to large-scale industrial operations. Let’s dive into the core features, key advantages, and primary applications of food packaging machines, which have revolutionized the packaging landscape.

Key Features of Food Packaging Machines

Food packaging machines are equipped with advanced technologies that simplify and optimize the entire packaging process. Most modern machines are designed to handle a wide range of food products from dry snacks and frozen foods to liquids and perishable goods. Some of the most common features include:

1. Versatility and Adaptability: These machines are engineered to handle various packaging types such as pouches, bags, trays, and even bottles. They are suitable for both single-serve and bulk packaging, offering flexibility to meet different packaging requirements.

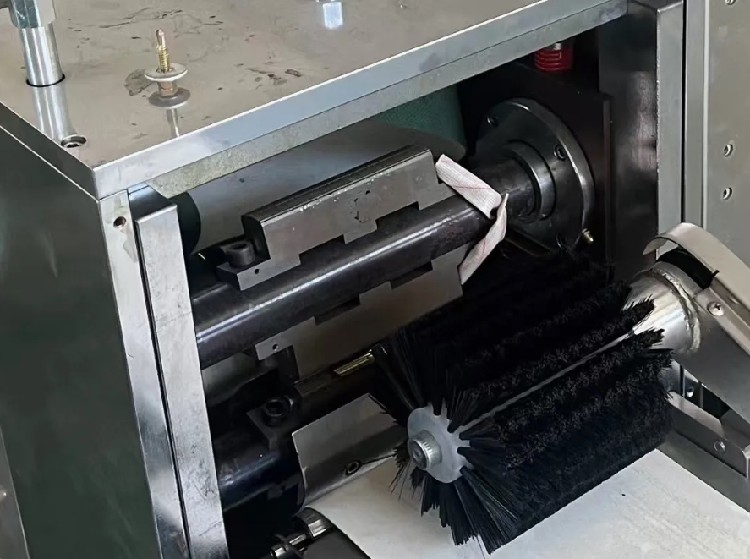

2. Automation: A key feature of food packaging machines is their high degree of automation. These machines are capable of performing multiple tasks such as filling, sealing, labeling, and even quality checks without requiring significant human intervention. This reduces labor costs and enhances production speed.

3. Precision and Consistency: Food packaging machines offer high precision in terms of portion control, ensuring that each package contains the exact amount of product. This is essential for both cost efficiency and customer satisfaction, as it minimizes waste and ensures product uniformity.

4. Hygiene and Safety: Given the perishable nature of food products, hygiene is a priority in food packaging. These machines are designed with materials that are easy to clean and maintain, ensuring compliance with stringent food safety standards.

Key Advantages of Food Packaging Machines

Investing in food packaging machines offers numerous benefits particularly for companies, aiming to scale their operations while maintaining quality and efficiency. Some of the most significant advantages include:

1. Increased Production Speed: Manual packaging processes can be time-consuming and prone to human error. Automated food packaging machines significantly speed up production, allowing businesses to meet high demand with fewer resources.

2. Improved Product Quality: These machines help maintain consistent product quality by minimizing human error and ensuring that food items are packaged in optimal conditions. Packaging is done quickly and efficiently, preserving the freshness, taste, and texture of the food product.

3. Cost-Effective Operations: Although food packaging machines may require an initial investment, they are cost-effective in the long run. Reduced labor costs, lower waste, and enhanced operational efficiency translate to a significant return on investment.

4. Sustainability: Many modern food packaging machines are designed with sustainability in mind, incorporating eco-friendly packaging materials and energy-efficient operations. This helps companies align with growing consumer demand for environmentally conscious practices.

Applications of Food Packaging Machines

Food packaging machines are used across a broad spectrum of the food industry with each machine tailored to suit specific needs. Some of the most common applications include:

1. Snack Foods: Machines designed for packaging snack foods like chips, nuts, and granola bars are built to preserve freshness and extend shelf life. These machines typically handle the production of sealed bags which keep snacks crisp and protected.

2. Beverages: For liquid products such as juices, dairy, or bottled water, food packaging machines ensure precise filling and sealing to prevent contamination and maintain product quality.

3. Frozen Foods: Packaging frozen foods such as vegetables, ready meals, and frozen desserts requires specialized machines that can handle low temperatures while maintaining efficiency. These machines ensure that the packaging is airtight and able to withstand freezing temperatures without compromising product quality.

4. Fresh Produce: Machines used for fresh produce packaging are designed to preserve the integrity of fruits, vegetables, and other perishables. They often feature modified atmosphere packaging (MAP) to extend the shelf life of fresh items.

5. Confectionery: The confectionery industry benefits greatly from food packaging machines that can handle delicate items like chocolates, gummies, and candies. These machines ensure that the packaging protects the product from damage while enhancing its visual appeal.

Conclusion

In today’s fast-paced food industry, food packaging machines are an essential investment for businesses looking to stay competitive. Their ability to streamline packaging operations, enhance product quality, and boost efficiency makes them invaluable assets to any food production facility. With the continued advancement in packaging technology, these machines offer innovative solutions that align with the evolving needs of the industry. Whether you're a small producer or a large-scale manufacturer, food packaging machines provide the tools necessary to ensure that your products reach consumers safely, efficiently, and sustainably.

Recommended products