Unleashing Efficiency: The Power of Plastic Granulator Machines

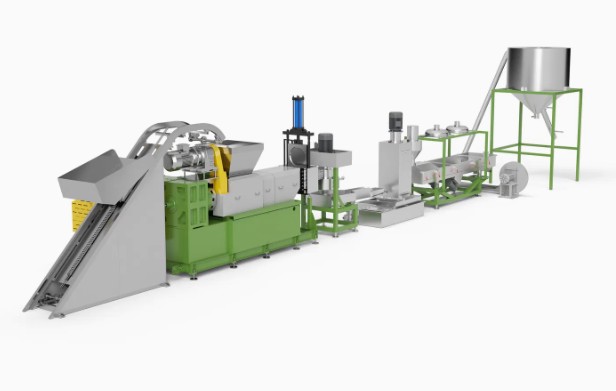

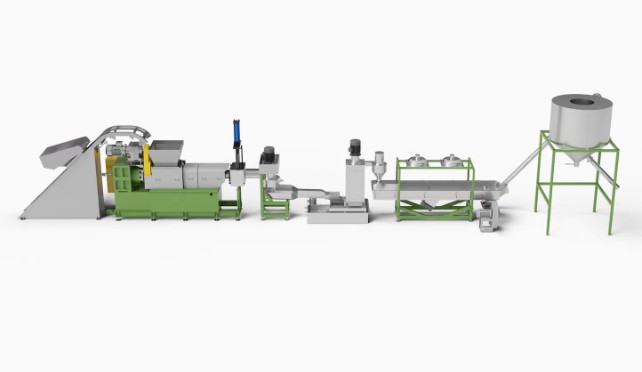

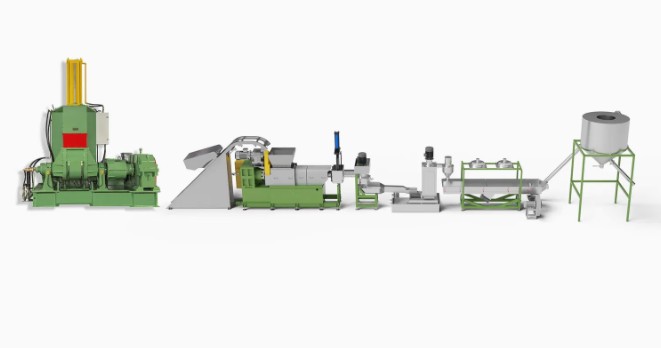

Product description

In an era where sustainability meets innovation, the significance of plastic granulator machines cannot be overstated. These machines have become essential tools in the recycling industry, contributing not only to waste reduction but also to the production of reusable plastic materials. Understanding the core features, benefits, and applications of plastic granulator machines reveals their substantial impact on both industries and the environment.

Key Features of Plastic Granulator Machines

Plastic granulator machines are designed to process various types of plastic waste, transforming them into manageable granules. These machines typically come equipped with powerful motors and high-speed rotor blades that enable efficient shredding and granulating of plastics. A crucial feature is the adjustable screen size, allowing users to customize the granule size according to specific needs. Many models also incorporate advanced safety mechanisms such as automatic shut-off systems and protective casing, ensuring safe operation for users.

Moreover, contemporary plastic granulators are designed for energy efficiency, reducing operational costs while maximizing output. Some units boast a compact design that makes them suitable for facilities with limited space, enabling ease of integration into existing workflows. The versatility of these machines further supports a range of plastics including polyethylene, polypropylene, and polystyrene, making them suitable for diverse processing requirements.

Advantages of Using Plastic Granulator Machines

The primary advantage of using plastic granulator machines lies in their contribution to a circular economy. By reducing plastic waste to granules, these machines facilitate the recycling process, making it easier for businesses to repurpose materials. This not only helps in conserving resources but also enhances the industry’s economic viability. Granulated plastic materials can be reused to manufacture new products, thus addressing the issue of plastic pollution directly.

Additionally, their efficiency translates into significant cost savings. By streamlining the recycling process, companies can reduce their waste disposal expenses while increasing their recycling rates. The machinery often operates with low maintenance needs, which further enhances their cost-effectiveness over time. Furthermore, by investing in these machines, companies can fulfill sustainability goals which are increasingly becoming important to consumers and regulatory bodies alike.

Application Scenarios of Plastic Granulator Machines

Plastic granulator machines find applications across various industries. In manufacturing, they are used to recycle scrap plastic generated during production processes. This recycling allows companies to maintain a sustainable operation by minimizing waste and reintroducing materials into the production line.

They are also indispensable in plastic recycling centers, where they handle large volumes of post-consumer plastics. Here, the machines help convert discarded plastic products such as bottles and containers into reusable granules for a wide range of applications. In addition, businesses in the automotive, packaging, and construction industries utilize plastic granulator machines to manage plastic waste and contribute to sustainable resource management.

Conclusion: A Vital Asset for Sustainable Practices

In summary, plastic granulator machines are pivotal in advancing recycling initiatives and promoting sustainability. Their powerful features, efficiency, and versatility make them valuable assets for a variety of applications across industries. By facilitating the conversion of plastic waste into reusable materials, they play a crucial role in reducing environmental impact and supporting businesses' efforts towards sustainable practices. Embracing the functionality and advantages of plastic granulator machines is a step forward in building a more sustainable future.

Recommended products