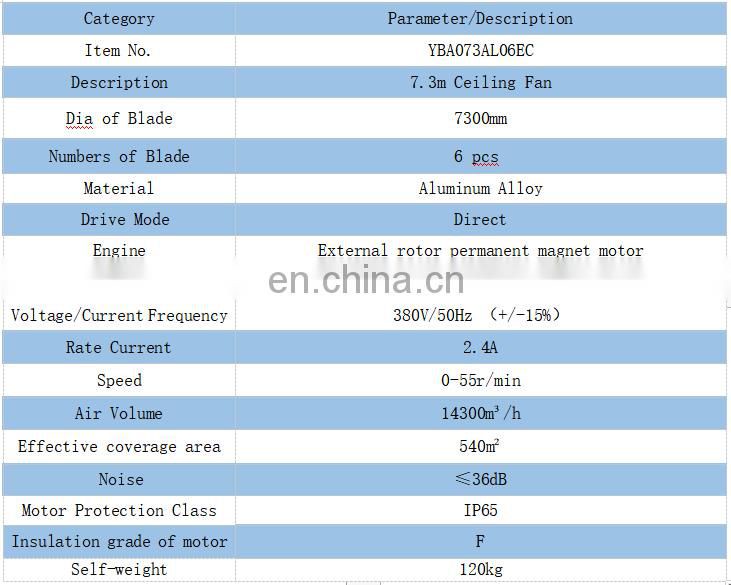

7.3m 24ft Industrial Ceiling Fan Energy-Saving Giant Industrial Fan Overhead Installing

Product description

Product Description

Product Description

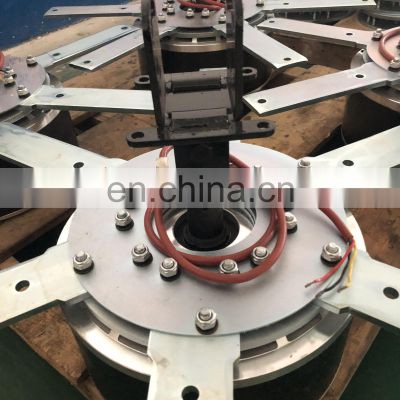

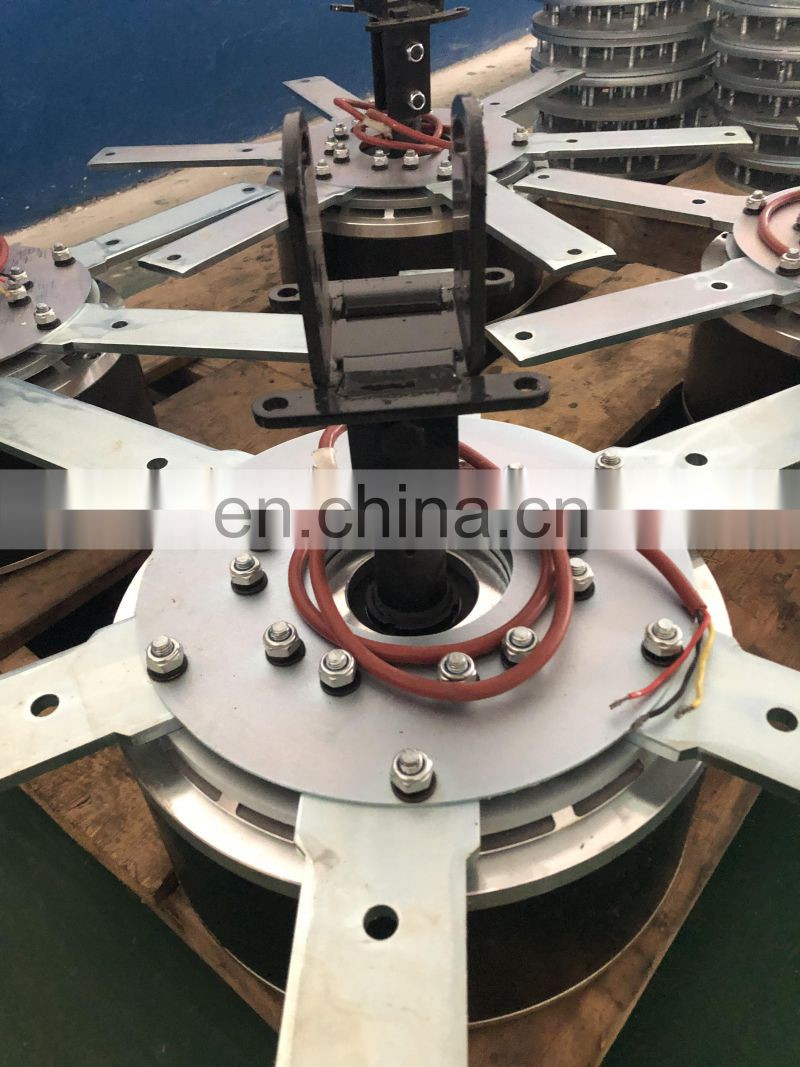

Driving device

The external rotor permanent magnet synchronous motor is

designed and manufactured by the company's shareholder with more than 20 years

of experience in permanent magnet motor design and manufacturing. High efficiency,

energy saving, energy consumption reduced by 30%, direct drive has no mechanical

deceleration, quiet, stable operation and lifelong maintenance free.

Fan blade

The fan blade surface is designed by large-scale hydrodynamics

simulation software, and the air supply effect is the best; The wall thickness is

increased, and four stiffeners are added in the inner cavity, which greatly improves

the bending and fracture resistance; High performance aluminum alloy 6005t6, 10%

higher than 6063; Fluorocarbon paint baking / electrostatic plastic spraying

treatment on the surface, wear-resistant and easy to clean.

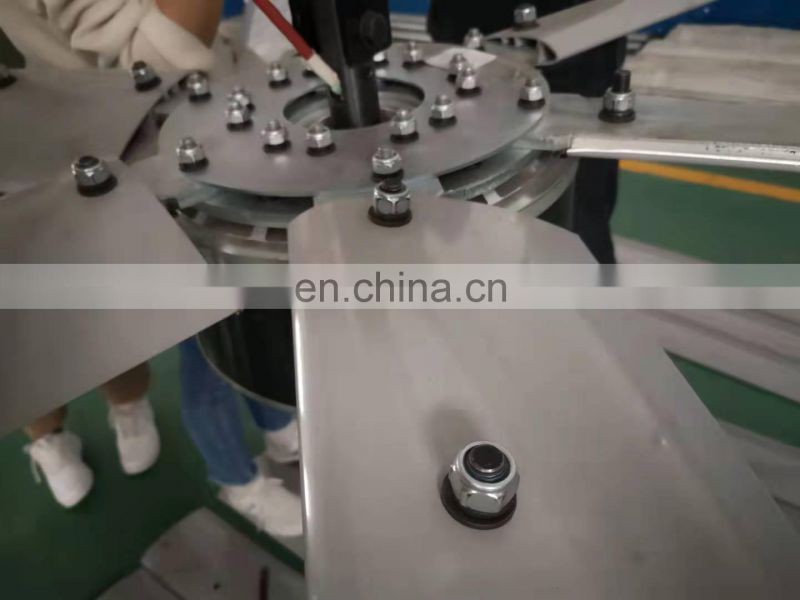

Chassis

Made of high performance structural steel; The upper and lower

double chassis are clamped with 12 high-strength bolts to connect all blades as a

whole and eliminate looseness and noise.

Fin

Safety devices and measures

Six safety protection:

1. Both sides of the connecting plate between the fan and the mounting beam are

folded to form a [shape to prevent deformation and bending;

2. The connection splint and the beam mounting plate are of deep sawtooth

structure, which are locked with each other to prevent falling off;

3. The connection of all parts of the fan is L-hook connection or mortise and tenon

connection and fully welded with double protection;

4. After the fan is installed, it shall be tightened and fixed on the building with 4 steel

ropes to prevent shaking;

5. Steel wire rope connection is added between motor shaft and building beam for

multiple protection;

6. The control system has complete overload, overcurrent and overheating

protection.

The external rotor permanent magnet synchronous motor is

designed and manufactured by the company's shareholder with more than 20 years

of experience in permanent magnet motor design and manufacturing. High efficiency,

energy saving, energy consumption reduced by 30%, direct drive has no mechanical

deceleration, quiet, stable operation and lifelong maintenance free.

Fan blade

The fan blade surface is designed by large-scale hydrodynamics

simulation software, and the air supply effect is the best; The wall thickness is

increased, and four stiffeners are added in the inner cavity, which greatly improves

the bending and fracture resistance; High performance aluminum alloy 6005t6, 10%

higher than 6063; Fluorocarbon paint baking / electrostatic plastic spraying

treatment on the surface, wear-resistant and easy to clean.

Chassis

Made of high performance structural steel; The upper and lower

double chassis are clamped with 12 high-strength bolts to connect all blades as a

whole and eliminate looseness and noise.

Fin

High performance structural steel is made by laser, and its bending and fracture

resistance is 15% higher than that of aluminum alloy, so as to eliminate deformation

and fracture.

Control system

As a shareholder of the company with more than 20 years of

experience in frequency conversion control system design and manufacturing, the

company specializes in the design and manufacturing of industrial large fans,

multiple protection such as electronics and logic operation, and super heat

dissipation devices, providing the most perfect guarantee for the safe, stable and efficient operation of fans.

resistance is 15% higher than that of aluminum alloy, so as to eliminate deformation

and fracture.

Control system

As a shareholder of the company with more than 20 years of

experience in frequency conversion control system design and manufacturing, the

company specializes in the design and manufacturing of industrial large fans,

multiple protection such as electronics and logic operation, and super heat

dissipation devices, providing the most perfect guarantee for the safe, stable and efficient operation of fans.

a fastening. All 12.9 / 8.8 high-strength bolts of domestic well-known brands are adopted, with guaranteed quality; Adopt mechanical locking nut to prevent loosening; With "loctite" locking glue, there is no hidden danger for permanent locking.

Safety devices and measures

Six safety protection:

1. Both sides of the connecting plate between the fan and the mounting beam are

folded to form a [shape to prevent deformation and bending;

2. The connection splint and the beam mounting plate are of deep sawtooth

structure, which are locked with each other to prevent falling off;

3. The connection of all parts of the fan is L-hook connection or mortise and tenon

connection and fully welded with double protection;

4. After the fan is installed, it shall be tightened and fixed on the building with 4 steel

ropes to prevent shaking;

5. Steel wire rope connection is added between motor shaft and building beam for

multiple protection;

6. The control system has complete overload, overcurrent and overheating

protection.

Terrui Internation CO.,LTD

Terrui International Co.,Ltd was founded in 2002 which is specialized in the development, manufacture and sales of livestock equipment.It has become one of the leading suppliers of drinking waterer, circulation fan, calf hutch and pen, veterinary accessories, plastic free stall and feeding fence and electric fencing in the domestic and world market.Since establishment, we have developed more than 100 products and got 25 patents. We have beening focusing on our product quality, and set up our own quality management system. The company operation is abliged by ISO 9001-2008 QMS after 2013.So far our products are prized all over the world and has been sold to more than 60 countries.Our goal is to make livestock healthier and more comfortable.

Dear friends, we strongly believe that we are able to support your business by the following ways:

1. High quality products and competitive prices;

2. Multiple new-design model options;

3. Strict quality control, fast delivery and good after-sales service;

4. We welcome OEM and ODM orders;

2. Multiple new-design model options;

3. Strict quality control, fast delivery and good after-sales service;

4. We welcome OEM and ODM orders;

Sincerely we hope to work together with you and get a win-win cooperation relationship in the future! Welcome to Shanghai Terrui International Co., Ltd!

We are committed to Serving for all esteemed dairies all over the world

Welcome to our factory Sincerely we hope to work together with you and get a win-win coop-eration relationship in the future!

Welcome to our factory Sincerely we hope to work together with you and get a win-win coop-eration relationship in the future!

Thank you very much for visiting our website and hope we have the products you like. When you contact us, we will provide you with the following services professionally and enthusiastically:

1. 24-hour product service for professional business personnel

2. The most up-to-date product catalogue

3. Accurate quotation of products you like

4. Free ODM & OEM sample service

5. Provide one-stop purchasing service for related products free of charge

6. One-stop customs clearance service to support all trade terms

7. Free visit to the factory reception service

8. Full order tracking data visualization service and free after-sales technical service.

9. International product sales consultant market analysis, planning, marketing and other services

9. International product sales consultant market analysis, planning, marketing and other services

Recommended products