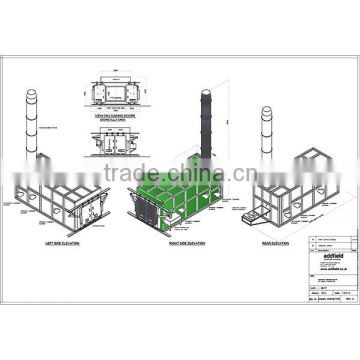

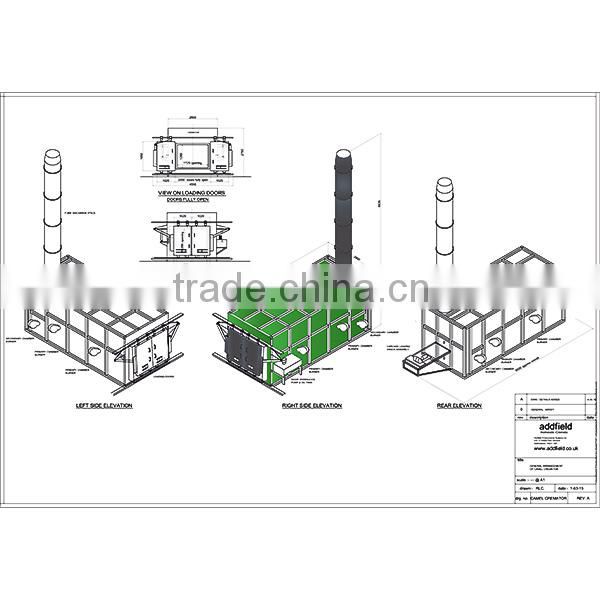

Camel Cremator

Product description

Product Description

Primary Cremation Chamber

Easy to maintain, thermally efficient, brick lined. (See page 6 for further information).

Three layers of refractory lining with an industry leading 180mm of insulation.

2000mm wide x 2000mm high x 5000mm deep chamber size.

Thermal insulation rated up to 1430°C.

Excess air and rapid cooling system

Cast floor refractory for ease of de-ashing

2000kg winch capacity to animal pull winch.

Secondary After Chamber

Two second gas retention time at minimum 850°C

Fully refractory lined and insulated.

Thermal insulation rated up to 1260°C.

Steel Work

The main structure is fabricated from a robust 8 and 10mm thick steel.

Internal surfaces protected with a tough acid resistant coating.

Fully seem welded construction.

Exterior Finish

Painted in a highly durable, weather resistant, two pack paint system that is baked on at 70°C.

Combustion Systems

4x Primary chamber burner .

2x Secondary chamber after burner.

Both burners come complete with integrated adjustable combustion air fan and adjustable fuel pressure dials. Environmentally friendly low NOx versions, with pulse firing capabilities to save fuel and maintain optimum cremation temperatures.

Electrical Systems

Weather resistant, IP65 rated. In accordance to BS7671 17th edition.

220v -240v, single phase 50-60Hz - 13-16 amp power supply required.

Control Systems

Addfield advanced PLC controlled. User friendly, rugged, heavy duty and plug and play.

Camel Cremator - Made in Britain

Certification

Specifically Designed for the Cremation of Camels

Addfield Environmental Factory

Recommended products