control system poultry

Product description

Product Description

Quality First, Reputation First

Yingtaida company is a wholly owned enterprise, founded in 2007, location in Anping city, Hebei ,China.Yingtaida company based on poultry farms in the design, construction, installation of equipment industry, can provide professional services for the domestic market.Products are laying chicken caged, Equipments for chicken group, slaughter equipment and so on.

Advantages:

1. All the parts are made from hot galvanized steel sheet, durability and feed health are made sure.

2. Optimized inclination angle makes feed flow smoothly.

3. Structure design of top silo saves space.

4. Hard and soft auger box can be adjusted between 0°and 45°.

5. Functions are very stable.

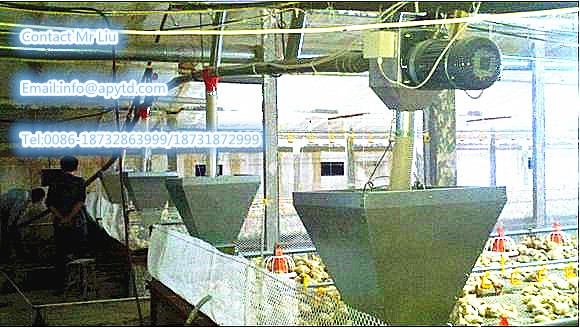

Working principle:

By using this system, the feed can be conveyed from the silo or manpower hopper into each feeding line in your chicken farms. There is a feed sensor at the end of main feed line, which controls the on/off of the motor automatically to

achieve

Working principle:

There is a feed sensor at the end of each feeding line which controls motor on and off to achieve feed delivery

automatically. The feed sensor is usually installed at one feed pan of the feeding line. The motor will start working and delivery feed when the feed pan (with sensor) lacks of feed and stop working when the feed pan (with sensor) is full of feed.

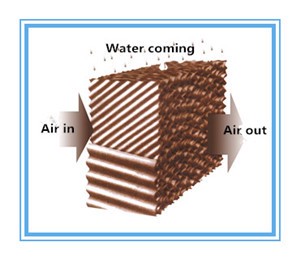

Cooling Pad Air inlet window Round & SQ fan

This system controls climate conditions, fresh air, humidity and temperature in poultry shed, it is vital for growing birds.

Use For Make Humidification Make Cooling Germicide and Disinfectant, This system saves the labor and the resources under the condition of assuring the optimum growth environment of the chicken. It can set an optimum working mode according to the local climate and raising environment.

Standard export package of chicken farming equipment for export is in container

1. Silo: disassembled, spare parts in carton box, galvanized sheet in bunch and in bulk

2. Feeder pan in carton box

3 .Feed pipe and support pipe, hopper in bunch in bulk

4. PVC pipe fitted with nipples in plastic bag, cups and spare parts in carton box

5. Fans and cooling pad: disassembled way or assembled way

6. Delivery Spring system by pallets

Grider and Mixer Spray disinfection machine Defeather Machine Air heater

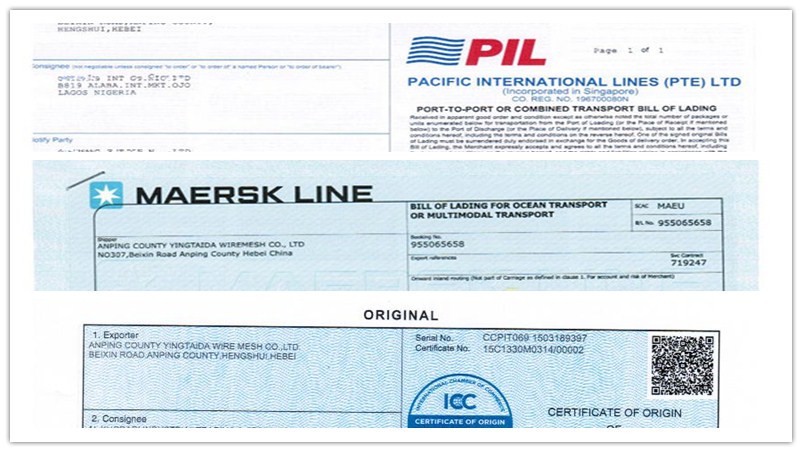

•We have good partner of shipping company: MSk, CMA,PIL, ANL..

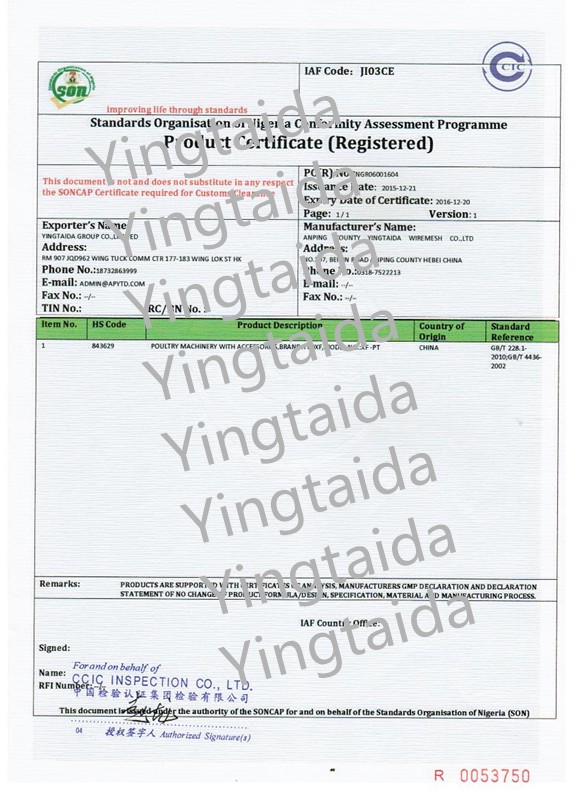

•We have certificate :SGS Soncap CE ..

•We free the products oringnal certificate for you

Recommended products