Super high voltage composite post insulator for Electrical industry

Product description

Product Description

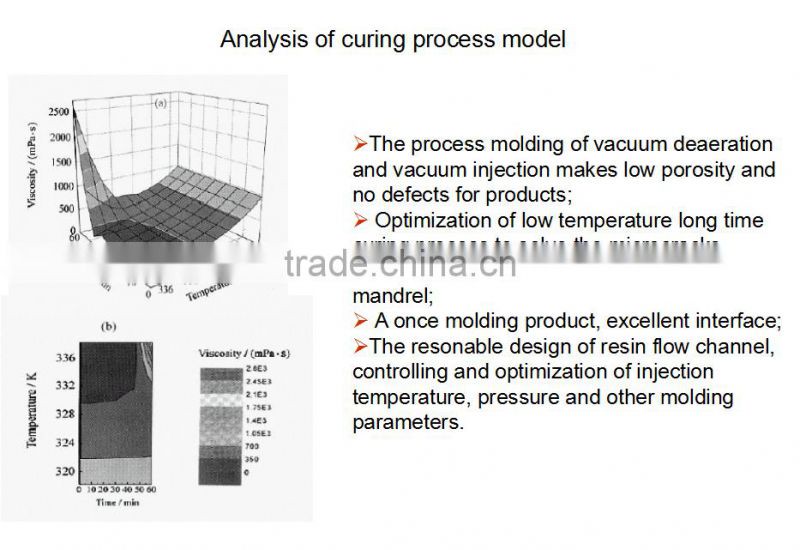

The super high voltage composite post insulator is made of liquid vacuum injection molding process, the product has less defects, no cracking, good interface performance, excellent mechanical properties and so on. At present, the maximum diameter of the product can be 320mm, the length can reach 2.6m.

Features: high modulus, low distortion, light weight and excellent explosion-proof performance, seismic performance; mechanical properties, the 280mm mandrel equivalent to winding process 315 mandrel.

Process method:Vacuum pouring epoxy resin after combined with a number of different diameter pultrusion mandrel.

Advantages: simple process, good mechanical properties in early stage;

Disadvantages: high porosity,resin debonding and cracking after long-term loading.

Process Technology

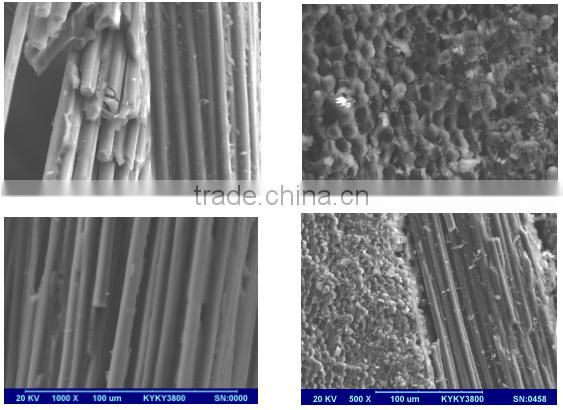

The following image shows the fiber surface is rough and attached resin. Resin matrix has a zigzag shape. The interface has a very good bonding properties between resin and fiber.

The test of bending strength and elastic modulus

| 1 | 2 | 3 | 4 | 5 | Average |

Strength(MPa) | 946 | 991 | 957 | 1324 | 1290 | 1101 |

Modulus(GPa) | 39.9 | 40.6 | 41.8 | 41.3 | 40.8 | 40.9 |

Certification

Recommended products