Product Description

20 ton per hour turn key complete biomass pellet production wood pelletization plant project engineering

20 ton per hour turn key complete biomass pelletization plant in Vietnam

Raw material: the local wood blocks, wood shavings, sawdust, straw and alfalfa

Device layout: several 508 type ring die pellet mill.

Production: 20 ton per hour.

Click Now for Catalogs & Factory Price!

Installation details on scene of pelletization plant

Highlights of pelletization plant

This complete wood pellet plant engineering uses dry material hopper which is used to store the dry materials from the drying machine. That can provide enough raw materials for the following steps and that can finish the whole production of the biomass pellet production plant by fewer man power.

Compared with the single cylinder drum dryer, the drum dryer with three cylinders requires small volume at the same yield. And the heat is enough which greatly meet the customers’ requirement.

We can customized your own biomass pelletization plant as your raw material, factotory and any requirements.

Click Now for Catalogs & Factory Price!

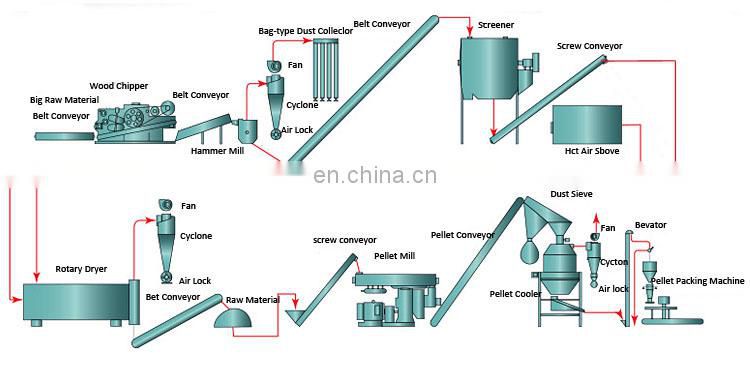

Technological process of pelletization plant

1. The raw materials like wood blocks is chipped by the chipper, then go into the wet material hopper.

2. After being ground by the crusher, the materials of this large turn key complete biomass pellet production plant will go into the drying machine.

3. The wet wood shavings will go through the belt and screening machine, then go into the drying machine in this wood pellet plant engineering progress.

4. After that, all the materials will go into the dry material hopper.

5. The dry materials will be sent into the screening machine by the belt then into the pellet mill by elevator.

6. Some dry wood shavings and sawdust will go into the pelletization plant directly after going through the belt, screening machine and elevator.

7. The pellet out of the pellet mill will be carried to the cooling machine of biomass pellet production plant by the belt then put into the finished product hopper.

8. The final step is to pack pellets by T bags or small bags.

Click Now for Catalogs & Factory Price!

Click Now for Catalogs & Factory Price!

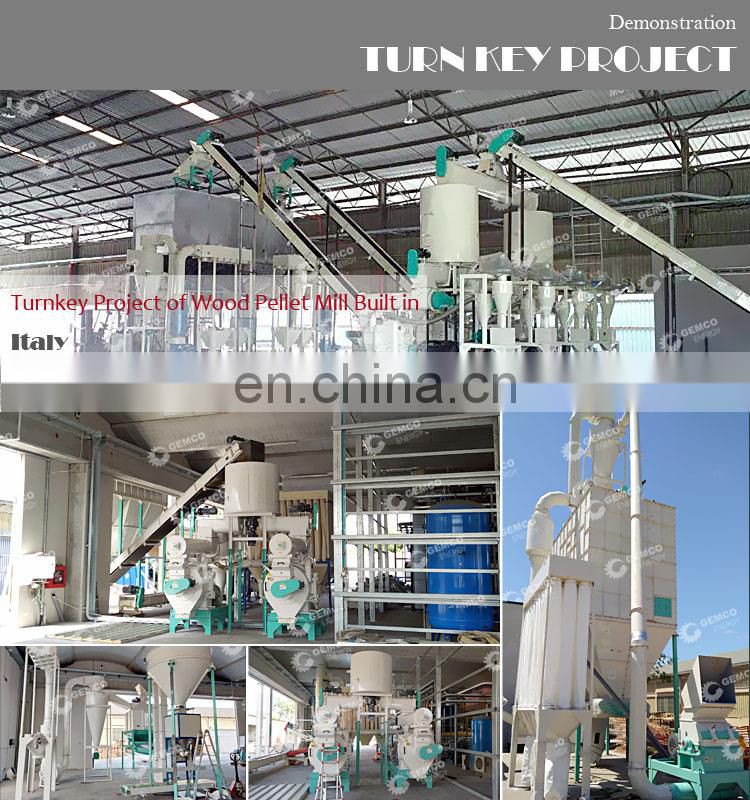

Successful case of biomass pellet production plant

Click Now for Catalogs & Factory Price!

Main part in complete pelletization plant

According to different capacity which our customers needs, we have a range of pellet mill in the complete wood pellet plant engineering to process the material, and meet their requirements. We have 1-20 ton per hour large complete biomass pellet lproduction plant.

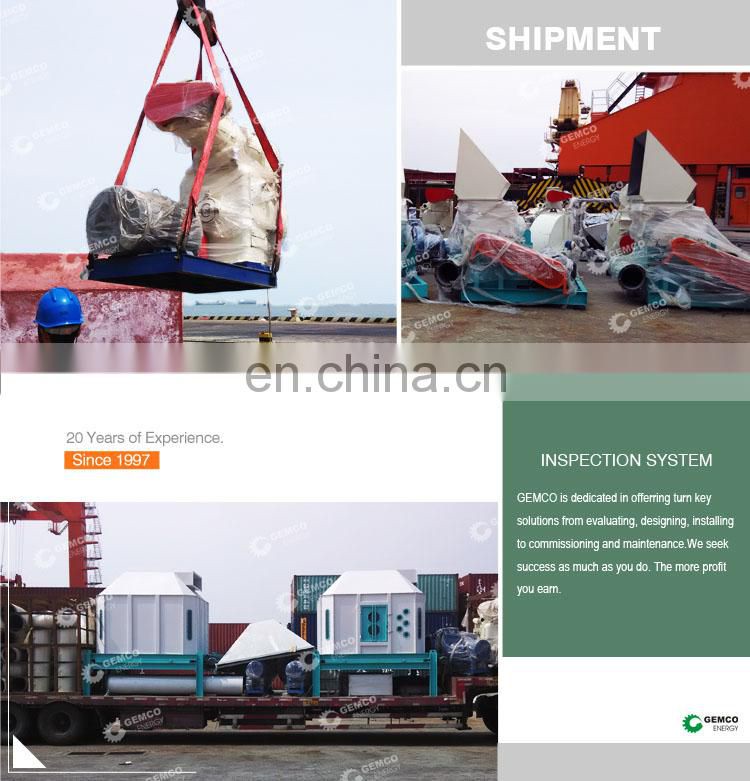

GEMCO is producing commercial large scale pellet mill for complete pelletization plant construction. We have rich experience in building biomass pellet production plant. We have professional sales men, engineers and professional techonical specialists forming a professional team, and we will help you to solve all the problems from transportation, installation, debugging, staff training, etc.

Click Now for Catalogs & Factory Price!

Customers & Certifications