100 cotton boys long sleeve t-shirt, cotton long sleeve blank t-shirt for children

Product description

Product Description

Key Features & Specification

Custom T shirt Silk Screen printing

1. Fabric composition: 100% cotton, CVC (65% cotton+35% polyester), TC (35% cotton+65% polyester), 100% polyester, etc.

2. Fabric: single jersey, interlock, pique, rib, spandex, viscose.

3. Weight: 140gsm, 160gsm, 180gsm, 200gsm, 200gsm++, etc.

4. Color: white, black, grey, yellow, red, blue etc and most welcome with customer require Panton

5. Size: standard European & USA size. Customer own size chart is most welcome

6. Workmanship: shoulder to shoulder tape, cover seam self neck, double stitches cuff and bottom

7. Print and embroidery available: silk screen print, rubber print, puff print, foil print, flock print, high density, crack print etc.

8. Samples finished time: 7days after confirmation

9. Your logo or brand can be put on, suitable for advertising and promotion.

10. Welcome of your design for making samples.

11. Small order quantity acceptable like 500pcs each color if we have stock fabric.

12. Production Type: Cotton T-shirts, Plain T-shirts, Round Neck T-shirt, Short Sleeve T-shirts, Sleeve less T-shirt, With Pattern T-shirts, Printing T-shirts for Unisex etc

13. Pls feel free to contact us for further details.

Notice: Order T-shirt, for a quotation to be clear...

1, Material and fabric weight? 100% Cotton, 100% polyester, cotton/poly blended, or Other Fabrics. Weight from 100gsm to 280gsm for T-shirt or Polo shirt.

2, Size and color? Europe size/Asia size/American size XS, S, M, L, XL, 2XL or 3XL-6XL? White color or other colors you prefer?

3, Target order quantity?

4, Logo Printing? Blank or With Pattern? If YES, Your detailed LOGO Attachment is much appreciated.

5, Packaging? Clear whether there are specific packaging requirements; such as the single package or 10pcs into one polybag; tag and so on?

7. Print and embroidery available: silk screen print, rubber print, puff print, foil print, flock print, high density, crack print etc.

9) Your logo or brand can be put on, suitable for advertising and promotion.

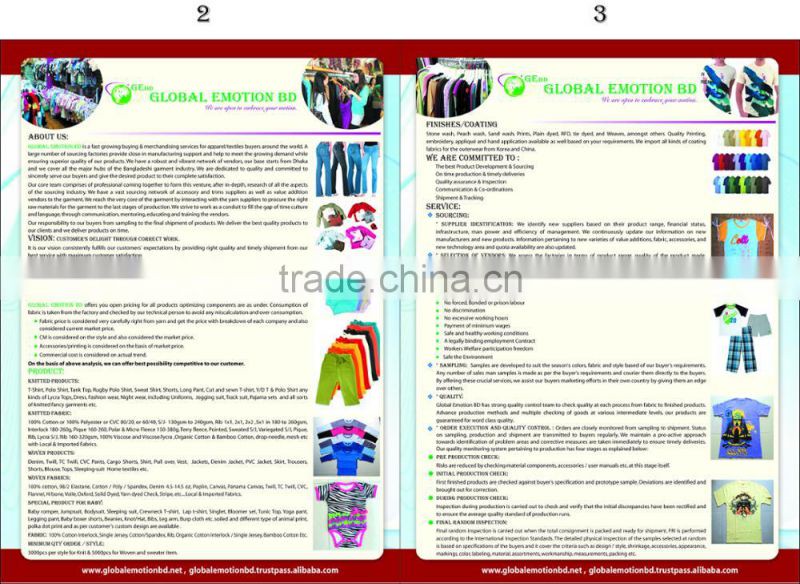

To introduce ourselves as one of the leading and most economical export oriented garments exporter in Bangladesh, which is equipped with most modern procedure to support the direct buyer. To facilitate our exports, we are registered and enlisted with respective authorities including Dhaka Chamber Of Commerce & Industry, BKMEA and export promotion Bureau under ministry of commerce. We welcome you to visit our factory as well as associate factories with the assurance that you will certainly be satisfied with our performance and working environments. However, prior notification for such visit will be highly appreciated to get the new order from your side.

Global Emotion BD Performing in the Sector with having Their own Manufacturing unit, For provide close-in manufacturing support and help to meet the growing demand while ensuring superior quality of our products. Our factory is BSCI audited also we have Oeko-tex & Sedex certificate.

also if we need to sourcing new factory depend on customer demand! We assess the factories in terms of product range, quality of the product made,

production capacity, facilities, financial capability, technology orientation, man power, working conditions, managerial efficiency and their overall quality policy. Once our initial assessment is over we exchange information with our principals and make a combined decision in approving an identified vendor.

Global Emotion BD engaged in the Producing & merchandising services for all kinds of knitted Garments include Socks item,with a spotless track record since its inception. Our activity is highly motivated by our passion for beauty and our willingness to meet our clients' and partners' needs and demands. Our strengths are flexibility, diversity and innovation. Our commitment to business ethics has earned us enormous trust. We intend to build on this by creating world-class products and services for our customers.

We provide special care and attention to the designers whose aim is to fulfill the exact design of the customer’s requirements in the garments industry

PRODUCTION PROCEDURES

LAB DIP: | Submit all lab dips asap-3 choices for each color to avoid delays with resubmissions. -see purchase order for dates required for lab dips. |

FIT SAMPLE: | Submit samples (size and quantity) as requested in purchase order. Follow measurement as spec & design as range sheet. Fabric quality/weight should be actual and available color is ok for fit sample -see purchase order for dates required for fit samples |

PRINT / EMB STRIKE OFF: | Submit 3pcs in each color /design. Base color s/b similar but print/emb color & quality need actual as request. -see purchase order for dates required for print & emb strike off. |

ACCESSORIES: | Submit all label/hangtag/patch/button/zipper etc for approval (3copy). -see purchase order for dates required for accessories. |

PP SAMPLE : | Submit sample (size and quantity) as requested in purchase order. Proceed to PP samples when all accessories, print/emb, labeling, hangtags and price tickets. -see purchase order for dates required for PP sample. |

BULK FABRICS: | Bulk fabric need one meter from each roll in each color from production for textile test. All color must be as customer quality standard – see purchase order for details. -see purchase order for dates required for Bulk fabrics.

|

LAB TEST : | Customers require lab testing by third party. Bulk fabrics must be submitted to ITS for testing. We pay for the testing and all re test will be charged to factory. Please ensure all bulk fabrics and garments must meet all customers required standard. |

| 1. Fibre contents (No tolerance). 2. Fabric weight (+/-3%) 3. Dimensional Stability (Shrinkage) 3 Wash (Maximum +/-5%) 4.Color Fastness To staining/water/dry rubbing/wet rubbing /light (Minimum 4) 5.Spirality after wash (Maximum 5%) 6.Pilling resistance (Minimum 3-4) 7. Azo/ phalate free (Formaldehyde content <75PPM). 8.Print durability (3 wash) |

PRODUCTION SAMPLE: | Submit samples (all size all color) as requested in purchase order. Sample fabrics quality/color/print/emb/accessories all need actual as production. -see purchase order for dates required for production sample. |

FINAL INSPECTION & SHIPMENT DATE: | Customers require final inspection by 3rd party. Bulk production sample counter copy must be submitted to its minimum 5days before inspection. Final inspection must be done by ITS minimum 4 days before shipment date. Buyer will pay for the 1st inspection and if any delay/re inspection or any other problem, all cost will be charged to factory. -see purchase order for dates required for final inspection and shipment. |

Check all approval samples carefully for measurements before sending to us – this will avoid delays for resubmissions.

Do not cut bulk until PP sample is approved by customer.

Submit shipping samples taken from bulk production for approval.

QC inspection will be arranged by third party/ Global Emotion BD. Factory must allow minimum 5days before sailing date for inspections.

Do not ship bulk order until shipping samples are approved and you are notified by buyer that the goods are ok to leave the factory.

Inspection Certificate will be issued by Buyer office after QC inspection and receipt of shipping samples.

|

Quality assurance:

In developing products and services, Quality assurance is any systematic process of checking to see whether a product or service being developed is meeting specified requirements. Many companies have a separate department devoted to Quality Assurance. A Quality Assurance system is said to increase customer confidence and a company’s credibility, to improve work processes efficiency, and to enable a company to better compete with others. Quality Assurance was initially introduced in World War II when munitions were inspected and tested for defects after they were made. Today’s Quality Assurance systems emphasize catching defects before thy get into the final product.

A program for the systematic monitoring and evaluation of the various aspects of a project, service, or facility to ensure that standards of quality are being meet. This is a part of Quality Management focused on providing confidence that

QUALITY REQUIREMENTS WILL BE FULFILLED

Our reputation and experience gained over the years in garments manufacturing made us a leading exporter in this competitive market leaving the manufacturers behind. We have fulfilled the challenging and difficult requirements of international buyers and maintained our quality with competitive pricing and on time delivery. Our commitment is to help clients and customers to find their ultimate product of choice.

Recommended products