Double layer 800kg per hour rice husk ring die pellet mill with automatice lubrication system

Product description

Product Description

Double layer 800kg per hour rice husk ring die pellet mill with automatice lubrication system

The information of rice husk ring die pellet mill

This rice husk ring die pellet mill is specially designed pellet mill which can process hard biomass material like eucalyptus, pine, birch, poplar as well as crop straw, bamboo sawdust shavings into biomass fuel. This rice husk ring die pellet mill effectively solves the difficulty in biological crude fiber granulation and the problem of poor quality. The host drive adopts high efficiency belt drive, the ring die is of quick detachable hoop type, feeder with frequency control feeding device which ensures uniform feeding. Our international advanced manufacturing technology can provide you with a variety of highquality molds according to your materials for your pellet machine, which can make your machine have a longer service life and lower power consumption, products with better quality.

Vertical ring die wood pellet mill machine VS Normal ring die wood pellet mill machine

-1, the normal ring die wood pellet mill machine is designed for animal feed pellets making, machine is small, total weight is much much less than Vertical ring die, so when the high fiber into the machine make the normal ring die working very hard, and very easy for sharking when working. Vertically ring die very heavy, much stable when working. It is designed for wood sawdust and other high fiber content materials.

-2, normal ring die pellet mill, the ring die rotary, the inside roller fixed, so it is a very big part rotary all the time. But for Vertical ring die pellet mill, the ring die fixed, inside rollers rotary. So if you explain to any engineers they will understand big part moving, the unstable is much bigger than small parts moving. It means, the normal ring die pellet mill is much easy broken down than the vertical ring die ( base on the engineering design)

-3, the normally ring die pellet mill, the mainly axis is horizontal and install the ring die at one side, and the like” hammer in horizontal condition”, so after a long time the horizontal axis will bend or broken very easily. But for vertical ring die pellet mill, install the axis and the ring die vertically can solve this problem.

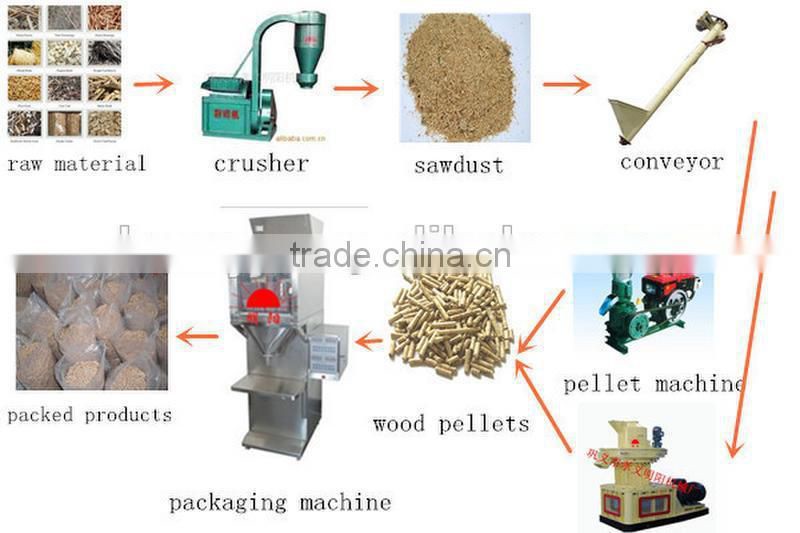

Working process of the rice husk ring die pellet mill:

The rice husk ring die pellet mill is easy to operate, we will install the machine and test machine well before delivery, once the user connects it with electric power, and the raw material is delivered into the pellet machine through a conveyor and then conveyed into a rotating ring die by a feeder.

Finely pulverized material will be pressed into ring die through two rotating press rollers. The resulting pressure compresses the material and extrudes it through the holes in the die. The pellet will be out directly.

Requirements for the raw materials:

Almost all kind of biomass materials are available for pellet mill. For example: wood, rice husk, sunflower shell, bagasse, fibrous waste, cotton waste, agricultural straw, farm waste, grass, alfalfa, bamboo, palm fiber or paper waste.(The moisture of the raw material should be within 10%-15%, otherwise, you either need a dryer or spray some water on it.)

We need to know

A.What capacity would your prefer?

B.What is your raw material(size,moisture)?

-----According to different raw material(such as hard wood,soft wood,straw,rice hust), capacity is different.

C.What is the voltage do you require?

---We will change it as your request.

FAQ:

1. What's your payment terms?

L/C, T/T or negotiation.

2. what's your MAQ?

The MAQ is 1 set.

3. what's the density of the pellets?

1.1-1.3t/m3.

4. What's the working life for the wearing parts( die and rollers )

1500-2000Hours .

5. What is your warranty?

We can extend the warranty to 1 years!

The packaging and shipping of rice husk ring die pellet mill

rice husk ring die pellet mill packaging with two layers, first layers is in PP bags,the second packing in the plywood cases

Recommended products