20% discount factory price 320kg per hour log briquette making equipment with long service life

Product description

Product Description

The information of log briquette making equipment

log briquette making equipment is our hot sale charcoal making machine. The favored material for making BBQ charcoal are hardwood which have higher lignin than softwood, the common hardwood are mahogany, teak, walnut, oak, elm, aspen, poplar, birch, maple, etc. 90% of the mixture for making charcoal briquettes are char( carbonized biomass material). To make the briquettes easy to form and light, usually you need to add coal and binder to the char.

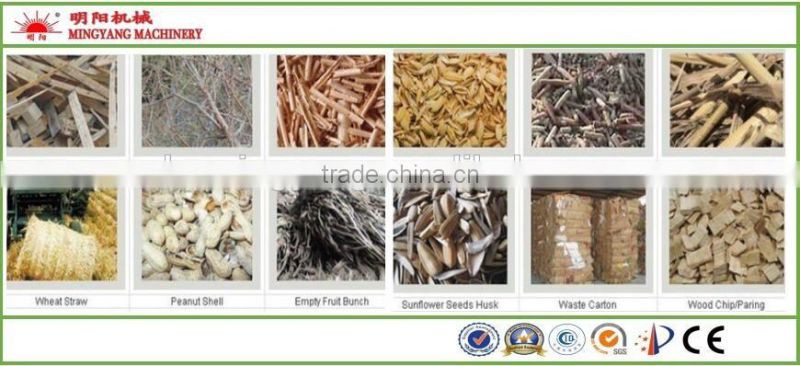

The raw material of log briquette making equipment

Any types of Agro-forestry waste and forest waste can be used for make briquettes Such as maize stalks, soybean stalks, broomcorn stalks, cotton stalks, rape stalks, peanut plants, sunflower stalks, bamboo sawdust, bagasse , wood chips, rice husk, coffee husk, coir pith, jute sticks, groundnut shells, Bamboo, wood, straw dust, Mustard stalk and cotton stalks ,nutshell, coconut shell ,etc

The application of log briquette making equipment

square shape briquette equipment can make wood briquette of different diameters and different shapes from sawdust, wood branches, biomass,peanut shells and so on. the product of industrial briquette machine can be use for fuel .heating and so on .

The technical parameter of log briquette making equipment

The working principle of log briquette making equipment

These raw materials are crushed first, and then compressed into formed fuel products with high density and high calorific through machine pressing and heating.Through high temperature, purification and smoke abatement, carbonization furnace making semi-finished product into clean charcoals with no smoke, no taste and ,innoxious

Main Features of log briquette making equipment

1.)Our log briquette making equipment can make stick shape wood briquette of different diameter and different shape from agro-forest

2.)This log briquette making equipment can make stick shape rice husk briquette of different diameter and different shape from biomass and agro-forest waste.

3.)Raw Material of the agro-forest : Any type of Agro-Forestry waste can be used. But the Moisture Content Should be Less than 12%

The final product of log briquette making equipment

Out diameter of final briquettes is: 50mm, 60mm, 70mm, 80mm

How to make charcoal used log briquette making equipment

1.Crush the raw material into small pieces (diameter is about 3-5mm)

2.Dry the material by machine or dried it in the sun , till the moisture is less than 12%

3.Put the material into feed let of briquette machine

4.Produce the briquette stick from biomass material without any additive

5.Carbonized the briquette stick

The packing and shipping of log briquette making equipment

log briquette making equipment packing in the plywood boxes or wooden cases, then put into the 20 feet or 40 feet container in delivery as follows.

for us -------- Gongyi Xiaoyi Mingyang Machinery Plant

Gongyi Xiaoyi Mingyang Machinery Plant is located in Zhengzhou City, which is the biggest manufacturing base of charcoal making machinery.And we are the one of the earliest and largest manufacturers of renewable fuel & energy equipments and related machinery.

our company:

After 15 years development, now our company becomes an independent economic entity with the integration of science, engineering and trading department. our products are widely accepted in both domestic and world market, and also exported to more than 30 countries, such as England, Russia, Sweden, Poland, Iran, Sudan, South Malaysia, Indonesia, Vietnam, etc.

We have got many certification such as CE, ISO9001,BV ,etc.

Gongyi Xiaoyi Mingyang Machinery Plant

Web:

Any interest,please kindly leave your message,we will reply you as soon as possible

Recommended products