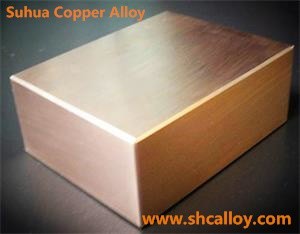

High Level Production Chromium Copper Alloy of Clean Mild Steel

Product description

Chromium copper has begun to replace beryllium copper as a general mold material in the mold industry due to its conductive and thermal conductivity, hardness, wear resistance and explosion resistance, and superior price compared with beryllium copper mold material. For example, shoe sole molds, plumbing molds, plastic molds that generally require high smoothness, connectors, guide wires, and other products that require high strength wires.

Chromium copper is used to ensure the performance through the combination of heat treatment and cold processing. It can obtain the best mechanical and physical properties. Therefore, it is used as a resistance welding electrode for general purposes, mainly as an electrode for spot welding or seam welding of low-carbon steel and coated steel plate, as well as an electrode holder, shaft and gasket material for welding low-carbon steel, or as a large mold, fixture for projection welding machines, mold or inlaid electrode for stainless steel and heat-resistant steel.

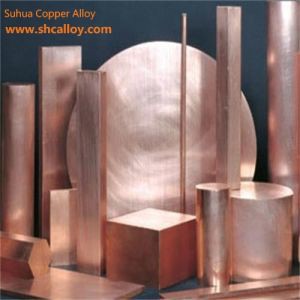

Recommended products