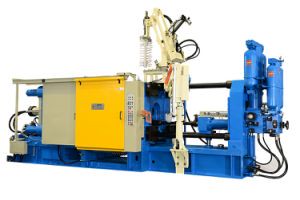

Customized Cold Chamber Aluminum High Pressure Copper Die Casting Machine

Product description

Post treatment of castings: The process of performing heat treatment, shaping, rust prevention treatment, and rough machining on cleaned castings. Post treatment of castings is the last step in the production of casting equipment. The process of removing a casting from a mold, removing excess parts outside the body, and polishing and finishing the inner and outer surfaces of the casting equipment. The main work is to clean the mold core and core iron. Cast Nonferrous Alloys Nonferrous alloys used to cast castings are a class of casting equipment. There are mainly cast copper alloys, cast aluminum alloys, and cast magnesium alloys.

A process device or consumable part that simulates the shape of a casting to form a mold cavity. To ensure the formation of a satisfactory cavity, the pattern should have sufficient strength and stiffness. A supplementary part attached to the top or side of the casting equipment to avoid defects in the casting. In a mold, the cavity of the riser is a container for storing liquid metal. Core box is a process casting equipment for molding cores from core sand. It can be made of wood, plastic, metal, or other materials.

Recommended products