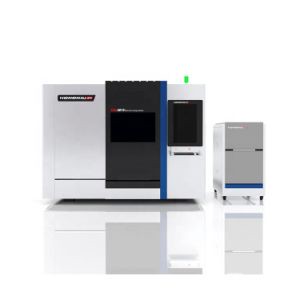

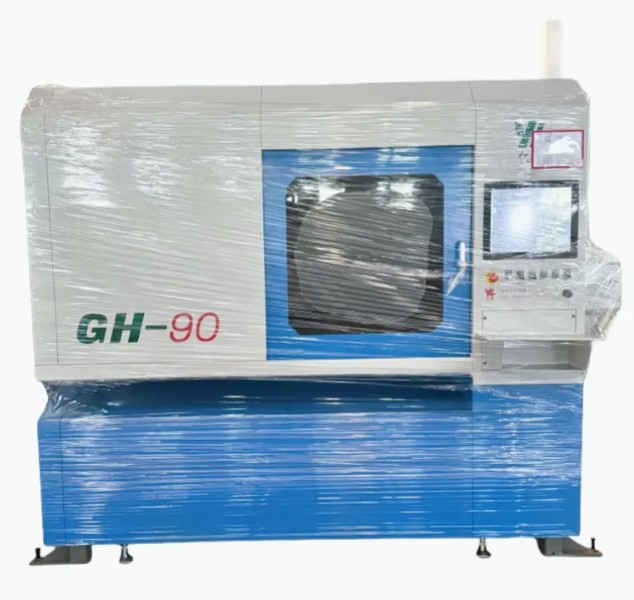

High Quality 500W-4000W Fiber Laser Cutting Machine

Product description

There are two types of laser cutting techniques: the first is pulse laser suitable for metallic materials, and the second is continuous laser suitable for non-metallic materials. The latter is an important application field of laser cutting technology. Several key technologies of laser cutting machines are integrated technologies of light, machinery, and electricity. The parameters of the laser beam, the performance and accuracy of the machine and CNC system directly affect the efficiency and quality of laser cutting in laser cutting machines.

Laser cutting is achieved by using the high-power density energy generated by laser focusing. Under the control of a computer, the laser is discharged through pulses to output a controlled repetitive high-frequency pulsed laser, forming a beam of light with a certain frequency and pulse width. The pulsed laser beam is transmitted and reflected through the optical path and focused on the surface of the processed object through a focusing lens group, forming fine, high-energy density light spots. The focal spots are located near the surface to be processed and melt or vaporize the processed material at high temperatures in an instant.

Recommended products