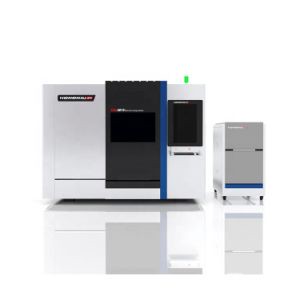

High Quality 500W-4000W Fiber Laser Cutting Machine

Product description

During the cutting process of a laser cutting machine, the beam of light is focused into a small focal point through the lens of the cutting head, achieving a high power density at the focal point. The cutting head is fixed on the z-axis. At this point, the heat input by the beam far exceeds the part of the heat reflected, conducted, or diffused by the material. The material is quickly heated to the melting and vaporization temperature. At the same time, a high-speed airflow blows out the melted and vaporized material from the coaxial or non coaxial side, forming holes for material cutting. As the focus moves relative to the material, the holes form continuous narrow slits, completing the cutting of the material.

Laser cutting processing replaces traditional mechanical knives with invisible beams of light. It has the characteristics of high precision, fast cutting, not limited to cutting pattern limitations, automatic layout saving materials, smooth cutting, and low processing costs. It will gradually improve or replace traditional metal cutting equipment. The mechanical part of the laser blade does not come into contact with the workpiece, so it will not cause scratches on the surface of the workpiece during operation; Laser cutting speed is fast, the incision is smooth and flat, and generally does not require subsequent processing; Cutting heat affected zone is small, plate deformation is small, and cutting seam is narrow (0.1mm~0.3mm); The incision has no mechanical stress and no shear burrs; High machining accuracy, good repeatability, and no damage to the material surface; CNC programming can process any flat drawing, and can cut large whole boards without the need for molds, which is economical and time-saving.

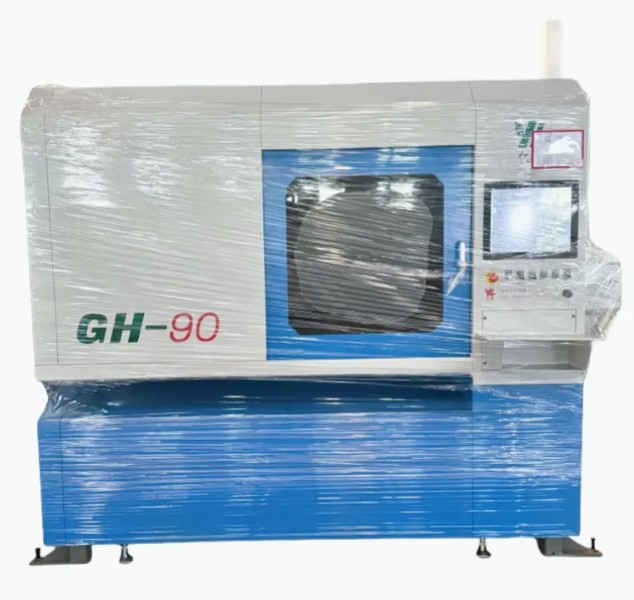

Recommended products