Factory Direct Sale Laser Bridge CNC Type Stone Cutting Machine for Granite

Product description

In the process of mechanical processing, the commonly used methods for sheet metal cutting include manual cutting, semi-automatic cutting machine cutting, and CNC cutting machine cutting. Manual cutting is flexible and convenient, but it has poor quality, large size errors, large material waste, and a large amount of subsequent processing workload. At the same time, the labor conditions are harsh and the production efficiency is low. The profile cutting machine in semi-automatic cutting machines has good quality in cutting workpieces, but due to the use of cutting molds, it is not suitable for cutting single pieces, small batches, and large workpieces.

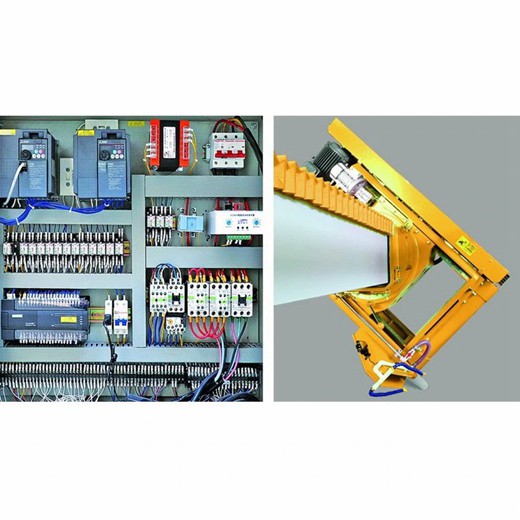

The cutting blade group of the stone cutting machine is located on the upper part of the stone conveying platform and placed on the frame, and the positioning guide plate is fixed between the cutting blade groups; The cutting blade group consists of an electric motor, a belt, a cutter wheel shaft, and a cutting tool, which is fixed on the cutter wheel shaft. This stone cutting machine can cut and process stones at different depths, and can process stones less than 1m3. It can turn waste into treasure, greatly saving stone resources and also helping to protect the environment. It can perform mechanical cutting and processing on various types of stones, with high processing efficiency. In addition, it effectively utilizes small stones, resulting in lower production costs.

Recommended products