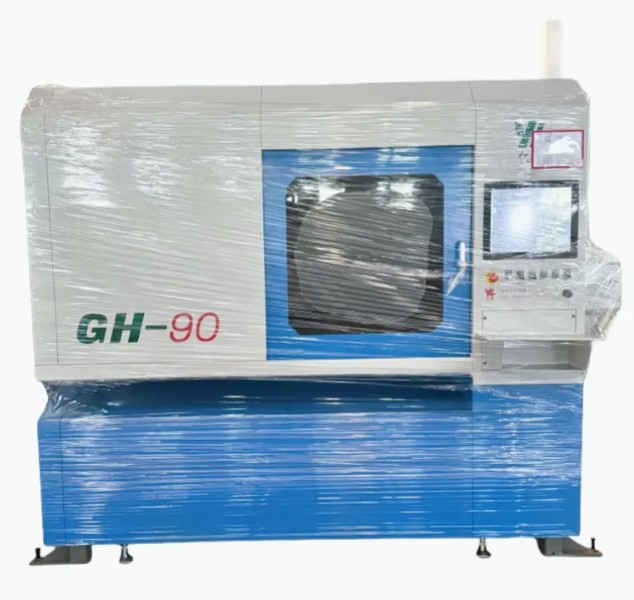

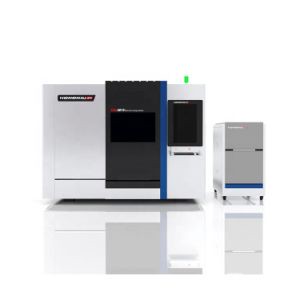

High Precision 500W-4000W Fiber Laser Cutting Machine

Product description

Laser cutting has fast speed, narrow cutting seam, small heat affected zone, good perpendicularity of cutting seam edge, smooth cutting edge, and a wide variety of materials that can be laser cut, including carbon steel, stainless steel, alloy steel, wood, plastic, rubber, cloth, quartz, ceramics, glass, composite materials, etc. With the rapid development of market economy and the rapid advancement of science and technology, laser cutting technology has been widely applied in fields such as automobiles, machinery, electricity, hardware, and electrical appliances. In recent years, laser cutting technology has been developing at an unprecedented speed, growing at a rate of 15% to 20% annually. Since 1985, China has been growing at a rate of nearly 25% per year. At present, there is still a significant gap between the overall level of laser cutting technology in China and advanced countries. Therefore, laser cutting technology has broad development prospects and huge application space in the domestic market.

Laser cutting processing replaces traditional mechanical knives with invisible beams of light. It has the characteristics of high precision, fast cutting, not limited to cutting pattern limitations, automatic layout saving materials, smooth cutting, and low processing costs. It will gradually improve or replace traditional metal cutting equipment. The mechanical part of the laser blade does not come into contact with the workpiece, so it will not cause scratches on the surface of the workpiece during operation; Laser cutting speed is fast, the incision is smooth and flat, and generally does not require subsequent processing; Cutting heat affected zone is small, plate deformation is small, and cutting seam is narrow (0.1mm~0.3mm); The incision has no mechanical stress and no shear burrs; High machining accuracy, good repeatability, and no damage to the material surface; CNC programming can process any flat drawing, and can cut large whole boards without the need for molds, which is economical and time-saving.

Recommended products