Customized Insulated Wall Roof Boards EPS/Glasswool Waterproof Sandwich Panels for Steel Warehouse Workshop Building

Product description

Core material is a key part of insulation sandwich panels, commonly used include polystyrene, rock wool, polyurethane, etc. These materials have good thermal insulation performance, which can effectively reduce heat transfer and reduce building energy consumption. The use of insulated sandwich panels helps to reduce building energy consumption and carbon emissions, in line with the concepts of green building and sustainable development.

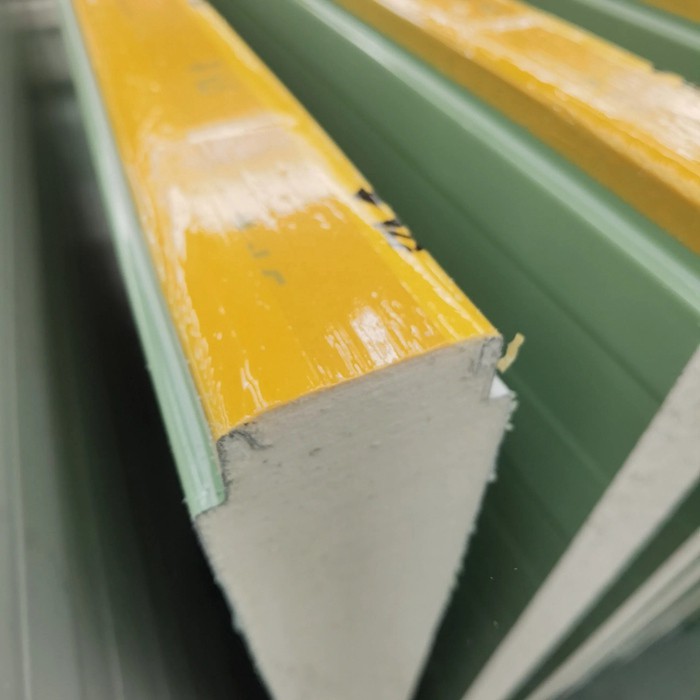

The insulation sandwich panel consists of two layers of metal sheets (such as steel plates, aluminum plates, etc.) and one layer of core material with excellent insulation performance. This sandwich structure enables the insulation sandwich panel to have both the strength and rigidity of a metal plate, as well as the insulation and fire resistance properties of the core material. The insulation sandwich panel adopts construction methods such as prefabrication and on-site splicing, and the installation process is simple and fast, shortening the construction period.

In terms of aesthetics, sandwich panels also perform excellently. The surface of metal sheets can be treated with various spraying, embossing, and other treatments, presenting a rich variety of colors and textures that can blend with different architectural styles. It is worth mentioning that sandwich panels also have advantages such as convenient installation and short construction period. Due to its light weight and high strength, construction methods such as prefabrication and on-site splicing can be used, greatly improving construction efficiency.

Sandwich panels have good insulation performance. Its core material can effectively block heat transfer, keeping the building warm in winter and cool in summer, reducing building energy consumption, in line with the concept of green building. Sandwich panels also need to pay attention to some issues during use. For example, metal sheets are prone to corrosion and scratches and require regular maintenance and upkeep; The selection of core materials also needs to be reasonably matched according to specific usage environments and needs.

Sandwich panels typically consist of two layers of metal sheets (such as steel plates, aluminum plates, etc.) and one layer of core material, which can be materials such as polystyrene, rock wool, polyurethane, etc. This sandwich structure allows the sandwich panel to have both the strength and rigidity of a metal plate, as well as the insulation, sound insulation, fire resistance, and other properties of the core material.

Recommended products