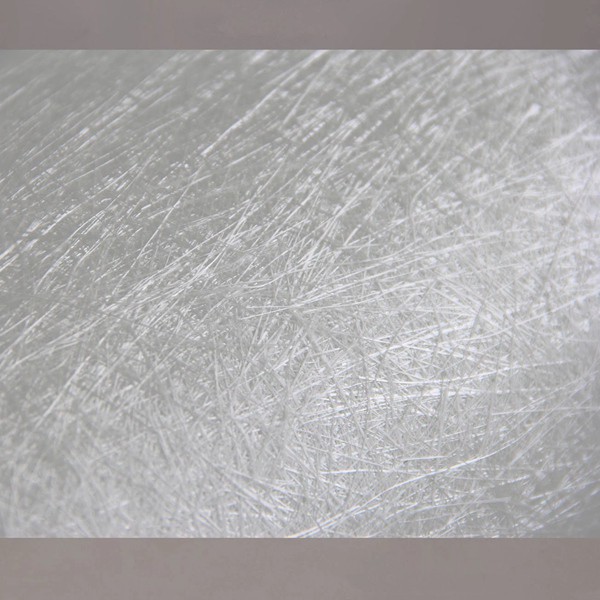

High quality Fiber Glass Fibre Fabric Continuous Filament Mat Use Thin Felt for Roof

Product description

Fiberglass felt has excellent physical and chemical properties. It has a high heat resistance temperature and can maintain stable performance in high-temperature environments, so it is often used for insulation of various high-temperature equipment. At the same time, fiberglass felt also has good insulation and sound absorption properties, which can effectively reduce energy loss and noise propagation, improve equipment operation efficiency and comfort. In addition, fiberglass felt also has characteristics such as corrosion resistance, insect resistance, and mold resistance, which can maintain stable performance in harsh environmental conditions and extend its service life.

Fiberglass felt, as an important industrial material, plays an irreplaceable role in multiple industries due to its unique characteristics and wide application fields. Next, we will explore in detail the characteristics and applications of fiberglass felt.

It should be noted that the production of fiberglass felt requires corresponding equipment such as an oven, mold, press, etc. Safety should be taken into account during the production process, such as wearing protective masks and gloves during processing. In addition, with the continuous development of technology, the application of glass fiber felt is also constantly expanding. For example, researchers used plasma chemical vapor deposition technology to grow nitrogen doped vertically structured graphene on the surface of glass fiber felt, preparing graphene glass fiber felt with adjustable infrared radiation performance, providing a new solution for fields such as photothermal oil recovery.

In terms of production technology, the production process of fiberglass felt includes steps such as impregnation, molding, compression, curing, exhaust, and polishing. Firstly, soak the fiberglass cloth or felt in the resin to allow the fibers to fully absorb the resin. Then, place the impregnated fiberglass cloth or felt into the prefabricated mold and machine press it into shape. Next, by compressing to remove excess resin and air, the glass fibers are made tighter. Subsequently, the compressed glass fiber is placed in an oven or cured at room temperature until the resin is completely hardened. Finally, perform exhaust and polishing treatment to make the product surface smooth and beautiful.

Let's take a look at the characteristics of fiberglass felt. Compared to fiberglass chopped felt, fiberglass felt has a longer fiber length and typically exists in the form of continuous fibers. This gives glass fiber felt significant advantages in mechanical properties and stability. In addition, fiberglass felt also has many characteristics such as high heat resistance, good insulation performance, high sound absorption rate, high exhaust purification efficiency, corrosion resistance, insect resistance, mold resistance, low absorption rate, good vibration resistance, flame retardancy, and light warranty. These characteristics make fiberglass felt have broad application prospects in multiple fields.

Recommended products