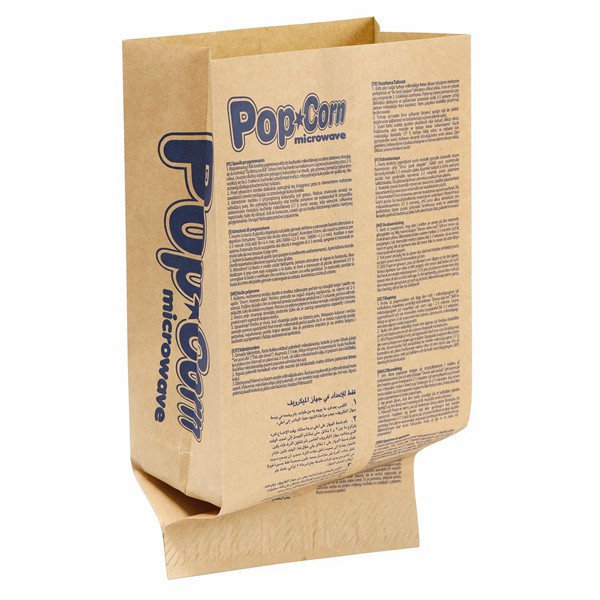

Food grade Biodegradable Bags of Popcorn in Bulk with Reflective Film

Product description

Finally, after strict quality inspection, qualified microwave popcorn paper bags can be packaged and shipped out to major supermarkets, cinemas, and other sales channels for consumer use.

After completing the above steps, the rolled paper will enter the paper seam bag making machine for bag making. During the bag making process, the machine will cut and sew the paper roll into a complete paper bag according to the preset size and shape.

Then, the printed surface paper and inner paper are laminated using a cold adhesive method. This composite method is not only sturdy, but also environmentally friendly, ensuring that the paper bag is not easily layered or damaged during use.

Next, the printed face paper will be subjected to film application on the laminating machine. This step is mainly to increase the durability and sealing of the paper bag, ensuring that it will not break or leak during microwave heating.

Microwave popcorn paper bags are not only convenient and easy to use, but also have environmentally friendly characteristics. Compared to traditional popcorn packaging methods, paper bags are easier to recycle and dispose of, reducing environmental pollution. At the same time, the lightweight and foldable nature of paper bags also makes them easy to carry and store, allowing people to enjoy delicious popcorn anytime and anywhere.

The design of microwave popcorn paper bags is clever and practical. It is made of special paper material, which can withstand the high temperature of a microwave while keeping the popcorn dry and fresh. The inside of paper bags is usually coated with a special layer of coating, which is used to absorb microwave energy and convert it into thermal energy, thereby quickly heating and bursting corn kernels.

Recommended products