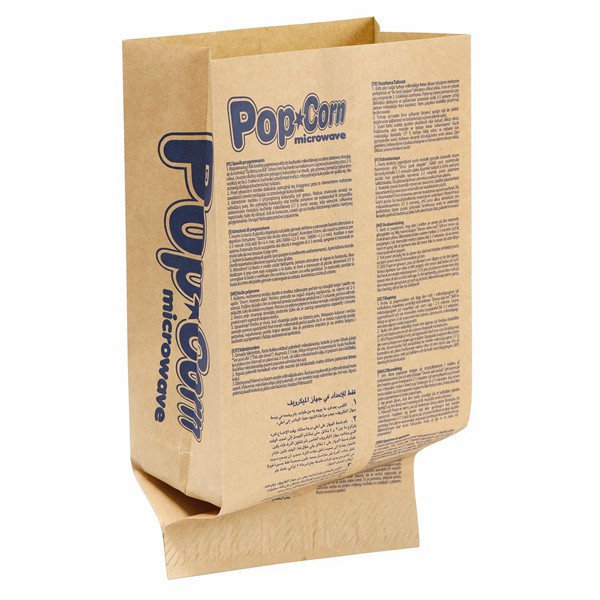

Customizable logo Biodegradable Bags of Popcorn in Bulk with Reflective Film

Product description

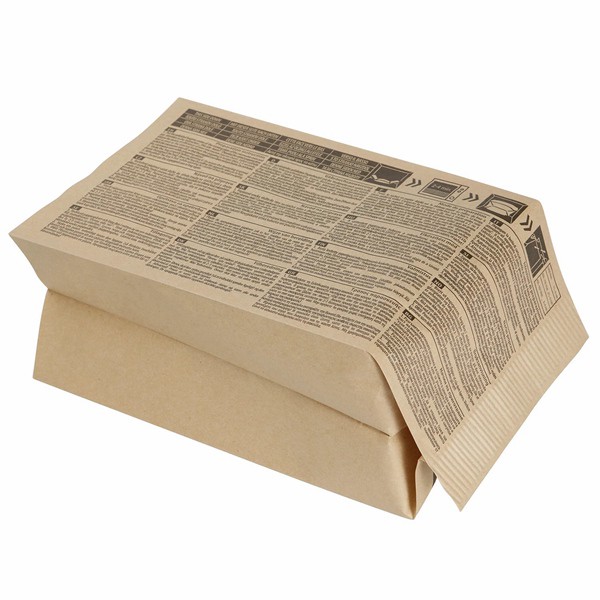

The composite paper is then loaded onto a printing machine or printing machine for positioning and gluing. The paper after printing glue is dried and sterilized through a medium temperature drying device to ensure the hygiene and safety of the paper bag. This step also enhances the firmness and durability of the paper bag.

Then, the printed surface paper and inner paper are laminated using a cold adhesive method. This composite method is not only sturdy, but also environmentally friendly, ensuring that the paper bag is not easily layered or damaged during use.

Next, the printed face paper will be subjected to film application on the laminating machine. This step is mainly to increase the durability and sealing of the paper bag, ensuring that it will not break or leak during microwave heating.

Firstly, advanced oil proof roll paper is used as the raw material. This type of paper not only has excellent oil resistance, but also ensures that the taste and quality of popcorn are not affected during the packaging process. Subsequently, these papers are processed by a flexible wire plate making printing machine to print various patterns and texts, which are both aesthetically pleasing and practical.

The production process of microwave popcorn paper bags is a combination of modern technology and traditional craftsmanship, aimed at manufacturing popcorn packaging that is both safe and convenient. The following are the detailed steps of the production process:

Recommended products