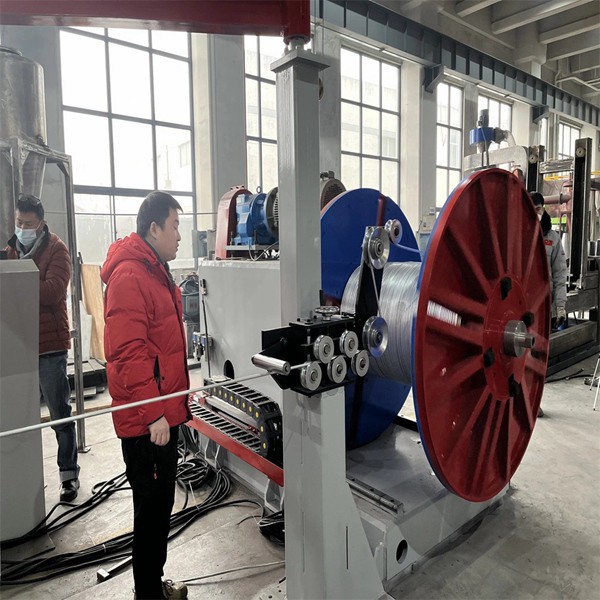

Factory Hot Sales Shielded Round Wire Copper Foil Wrap Taping Machine for Choke Transformer

Product description

Environmental protection has become one of the important trends in the development of modern industry. In the future, copper wire winding machines will pay more attention to environmental protection concepts, using environmentally friendly materials, low energy consumption technology and other means to reduce pollution and energy consumption in the production process. Digital transformation has become one of the important trends in the manufacturing industry. In the future, copper wire winding machines will achieve digital production and management, and improve production efficiency and quality through technologies such as the Internet of Things and big data.

The copper wire winding machine adopts an efficient and energy-saving motor and control system, which reduces energy consumption and noise pollution. At the same time, the equipment emphasizes environmental protection concepts in the manufacturing process, which meets the requirements of modern industrial green development. In order to meet the needs of different industries and users, copper wire winding machines will develop towards customization. Through modular design, flexible manufacturing and other technological means, rapid customization and personalized production of equipment can be achieved.

Copper wire winding machine is a device specifically designed to wind copper wire onto insulated wire cores or other substrates in a certain pattern. Its working principle is mainly driven by a motor, allowing the copper wire to be wound along a set path at a constant speed and tension under the action of a tension control device. At the same time, the equipment is also equipped with a precise control system to ensure that the position, angle, density and other parameters of the copper wire during the winding process are accurately adjustable.

With the rapid development of modern industrial technology, the wire and cable industry has increasingly higher requirements for production efficiency and quality. In this context, copper wire winding machines play an increasingly important role in the manufacturing process of wires and cables due to their efficient and precise performance characteristics. This article will provide a detailed introduction to the principle, characteristics, application areas, and future development trends of copper wire winding machines.

Recommended products