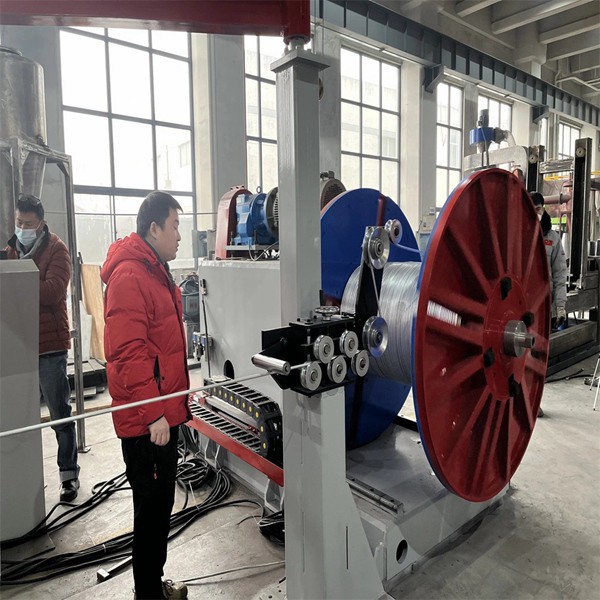

Automatic Sintering Line Copper Wire Wrapping Machine for Wire Harness

Product description

As one of the important equipment in the manufacturing process of wires and cables, copper wire winding machines provide strong support for the development of the wire and cable industry with their efficient and precise performance characteristics. With the continuous progress of technology and the continuous development of the market, copper wire winding machines will continue to play an important role in the wire and cable industry, promoting the sustainable development and innovation of the industry.

With the continuous development of the wire and cable industry, copper wire winding machines will face more opportunities and challenges. With the continuous progress of artificial intelligence technology, copper wire winding machines will develop towards intelligence. By introducing advanced sensors, controllers, and algorithms, equipment automation, intelligent control, and optimized production processes can be achieved.

Copper wire winding machines are widely used in fields such as wires and cables, communication, electronics, and automobiles. In the wire and cable industry, copper wire winding machines are mainly used to produce various types of power cables, communication cables, control cables, etc; In the field of communication, equipment can be used to produce fiber optic cables, coaxial cables, etc; In the field of electronics, copper wire winding machines can be used to produce lead wires for various electronic components, etc; In the automotive field, equipment can be used to produce automotive wiring harnesses, etc.

The copper wire winding machine adopts an efficient and energy-saving motor and control system, which reduces energy consumption and noise pollution. At the same time, the equipment emphasizes environmental protection concepts in the manufacturing process, which meets the requirements of modern industrial green development. In order to meet the needs of different industries and users, copper wire winding machines will develop towards customization. Through modular design, flexible manufacturing and other technological means, rapid customization and personalized production of equipment can be achieved.

The copper wire winding machine has a high-precision control system and tension adjustment device, which can ensure the quality and accuracy of copper wire winding and improve the performance stability of wires and cables. The equipment adopts a user-friendly design, making it easy to operate and understand. At the same time, the equipment also has fault self diagnosis and remote monitoring functions, making it convenient for users to maintain and upkeep.

Recommended products