Customized Spray Filling Capping Machine with CE Standard

Product description

With the continuous progress of technology and the constant changes in the market, liquid filling machines are also constantly developing and innovating. Future liquid filling machines will place greater emphasis on intelligence, automation, and environmental friendliness. By introducing technologies such as the Internet of Things, big data, and artificial intelligence, remote monitoring, fault diagnosis, and automatic adjustment of equipment can be achieved, improving the intelligence level of the equipment.

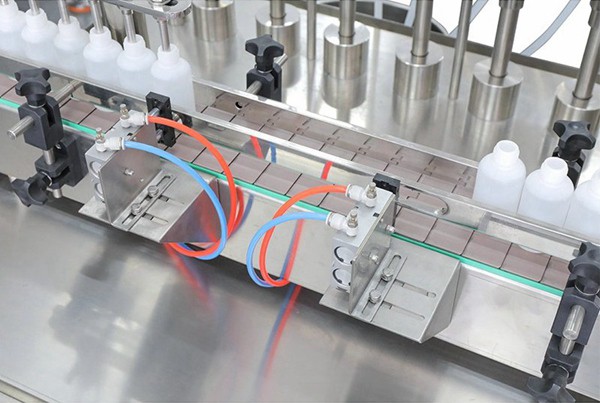

The liquid filling machine adopts automatic control, which can achieve high-speed and continuous filling operations, greatly improving production efficiency. By using high-precision measuring devices and control systems, we ensure that the amount filled each time meets the preset standards, reducing waste and errors. It is suitable for liquids of various viscosity and concentration, including oil, water, lotion, etc. Adopting advanced materials and processes for manufacturing, ensuring the stability and reliability of the equipment during long-term operation. The equipment is easy to operate and maintain, reducing operating and maintenance costs.

In modern and automated industrial production, liquid filling machines play a crucial role. Whether in the food, beverage, cosmetics, or chemical industry, liquid filling machines are one of the key equipment to ensure product quality and improve production efficiency. This article will provide a detailed introduction to the working principle, characteristics, application areas, and future development trends of liquid filling machines.

Some capping and filling machines, such as fully automatic capping machines, have a capping yield of over 99%, which reflects the advantages of capping accuracy and efficiency of capping and filling machines. In addition, some capping filling machines also have feeding valves composed of fast and slow filling, which can improve filling speed while ensuring filling accuracy, and the measurement error can even be less than 10 grams per barrel.

According to different filling principles, capping filling machines can be divided into various types, such as natural pressure automatic filling machines, working pressure automatic filling machines, etc. These different types of filling machines are suitable for liquid products with different viscosities and concentrations, as well as different production environments and requirements. The capping filling machine is an automated machine equipment that integrates filling and capping, with high efficiency, high precision, strong applicability, and good stability. It can achieve efficient and precise filling of liquid products, as well as automatic sealing of bottle caps, and is one of the indispensable important equipment in modern industrial production.

Recommended products